Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

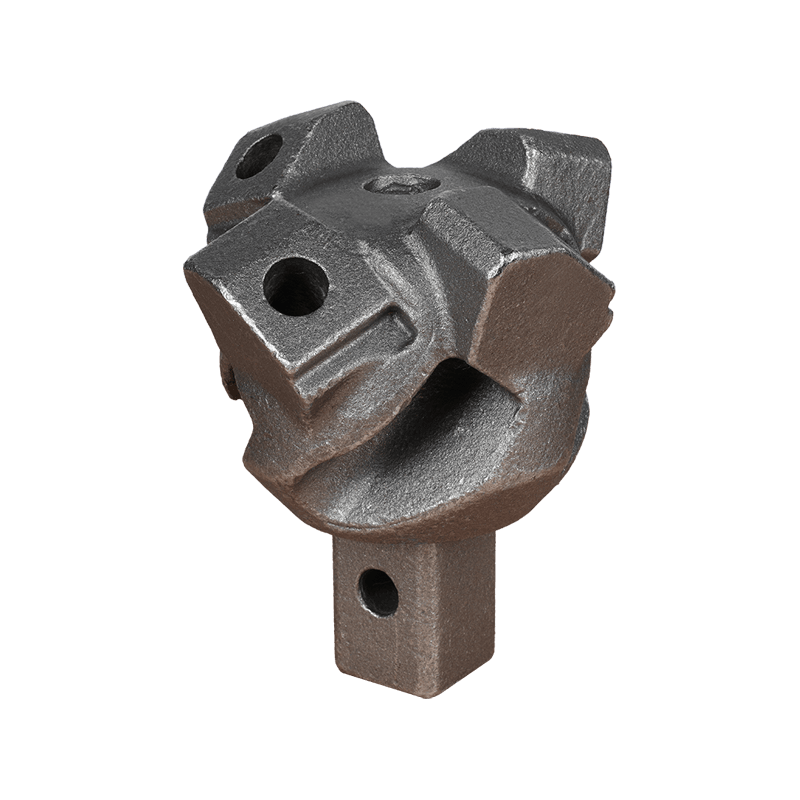

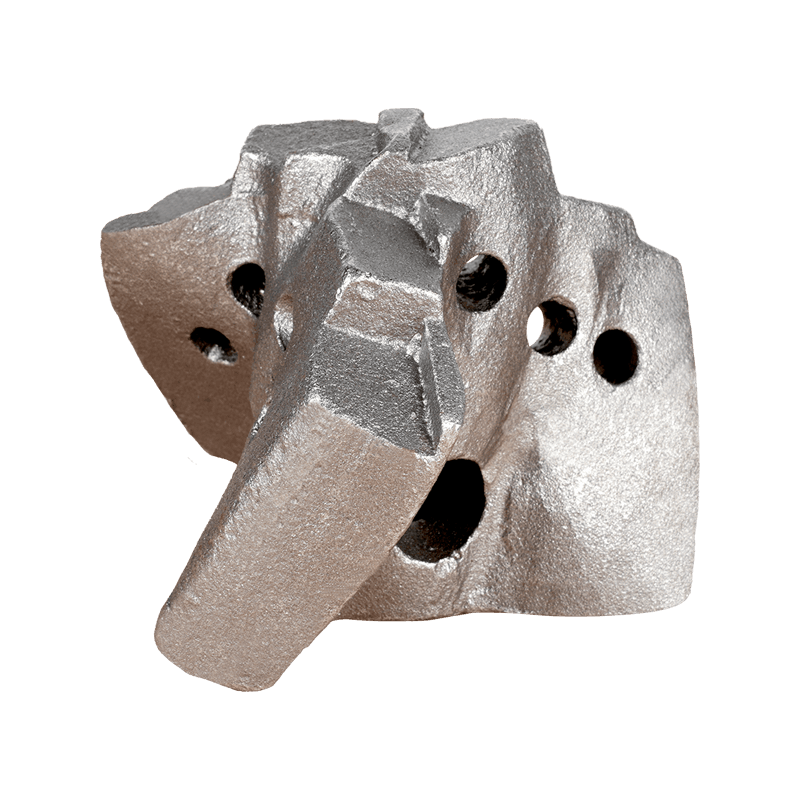

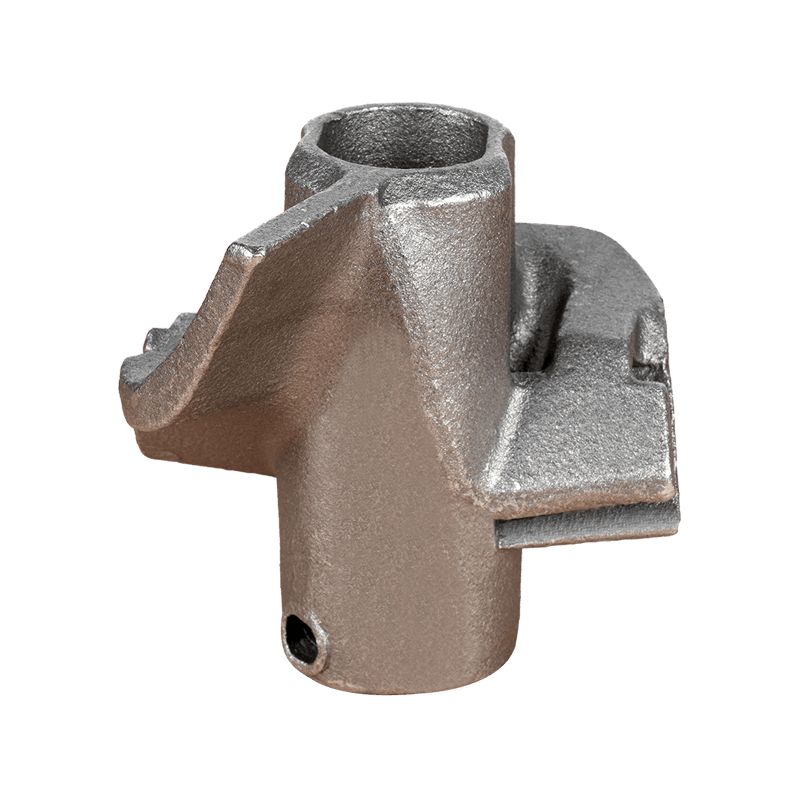

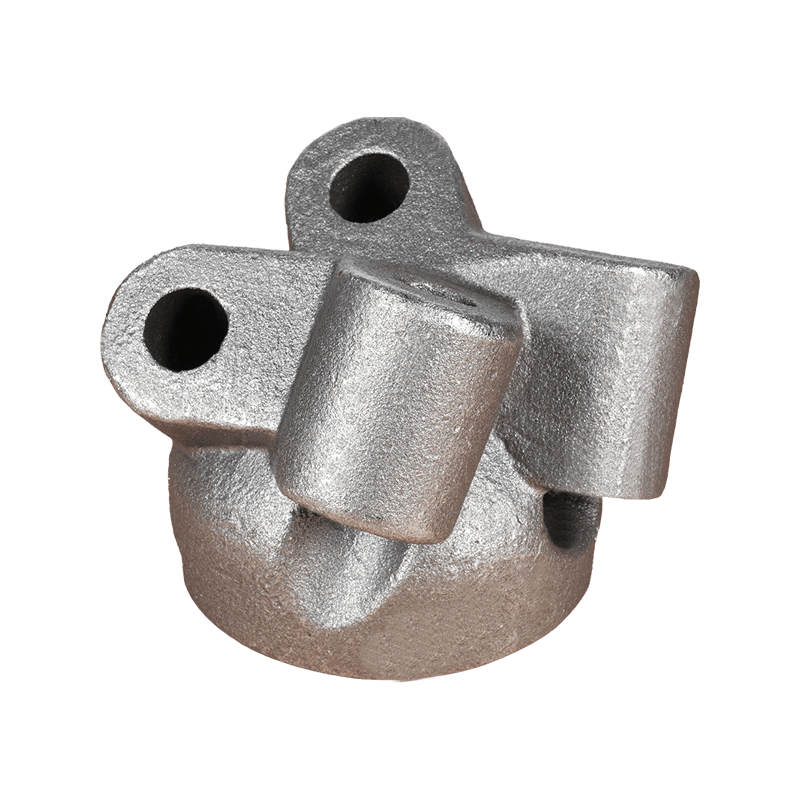

Drilling Rig Casting Steel Parts

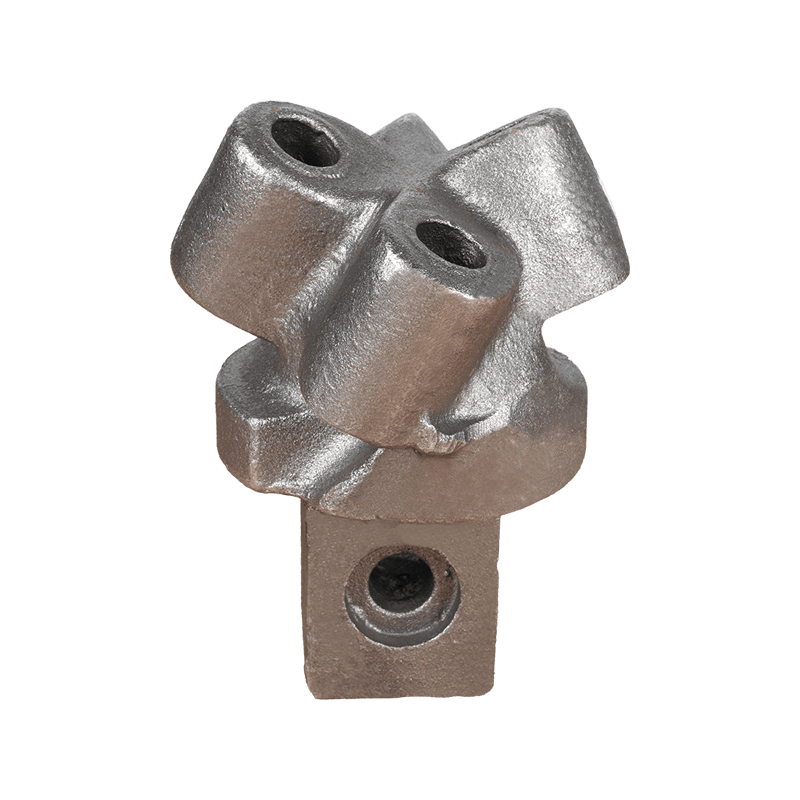

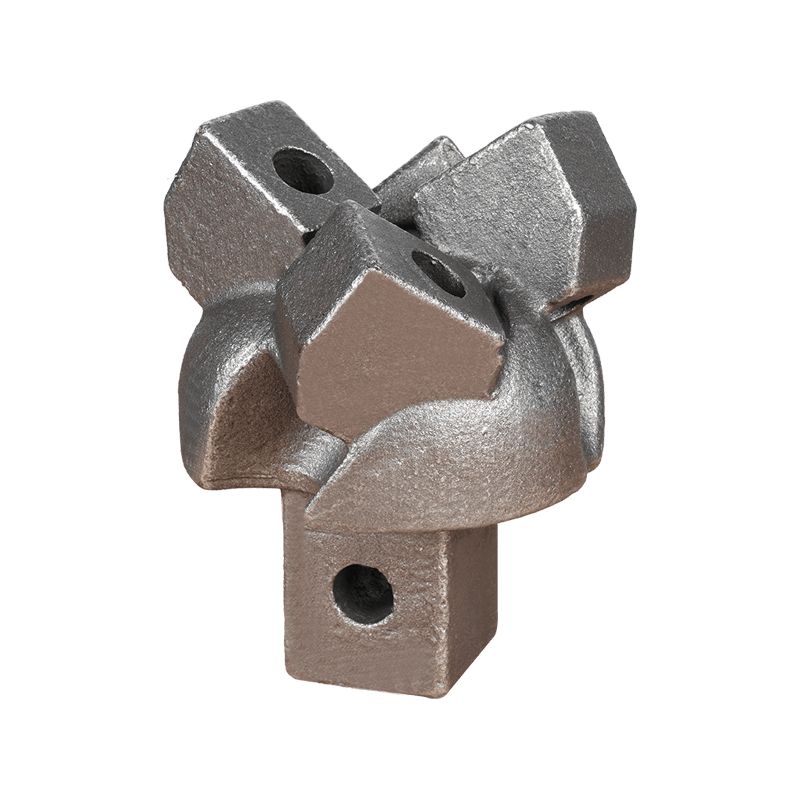

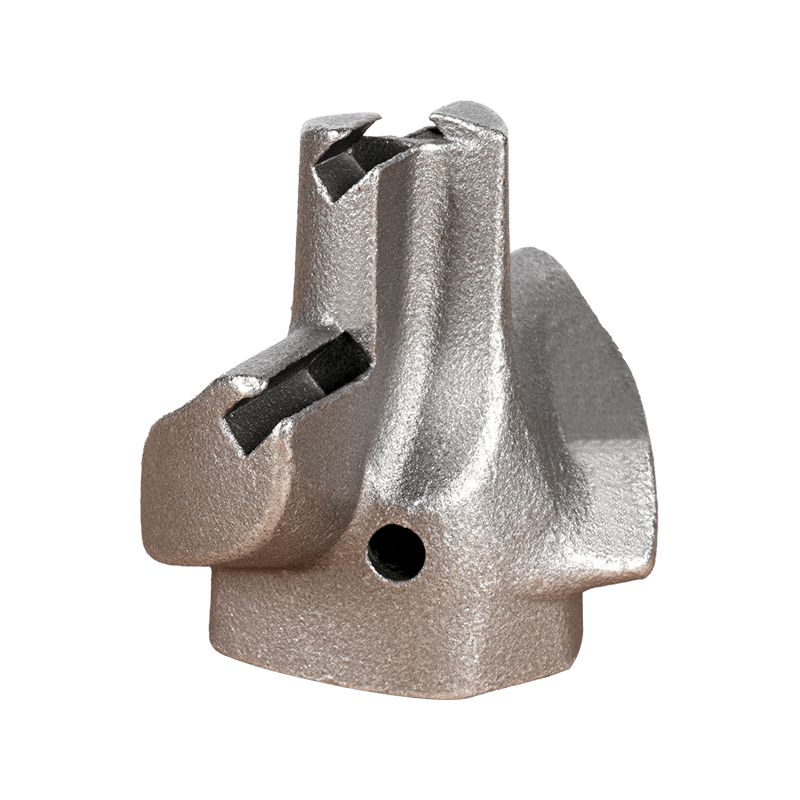

Drilling Rig Casting steel rotary drilling short arm Parts

Drilling booms are heavy-duty tool accessories used in construction machinery and equipment. They enable more efficient drilling operations. They are typically used to position, support, and guide the drill bit or other drilling tools, ensuring accurate positioning and stability during drilling.

Typically made of high-strength metal, they are wear-resistant, pressure-resistant, and offer high precision. They are widely used in drilling operations in steel structures, bridges, and mechanical equipment.

High Strength: Made of high-strength metal, they can withstand high pressure and impact, ensuring stable and reliable performance during operation.

Specially treated for wear resistance, they offer excellent wear resistance and long-term, damage-free use.

High Precision: They provide precise positioning and guidance, ensuring accurate drilling.

Various Specifications: Available in a variety of sizes and specifications to suit different models and specifications of drilling equipment.

Language

Language

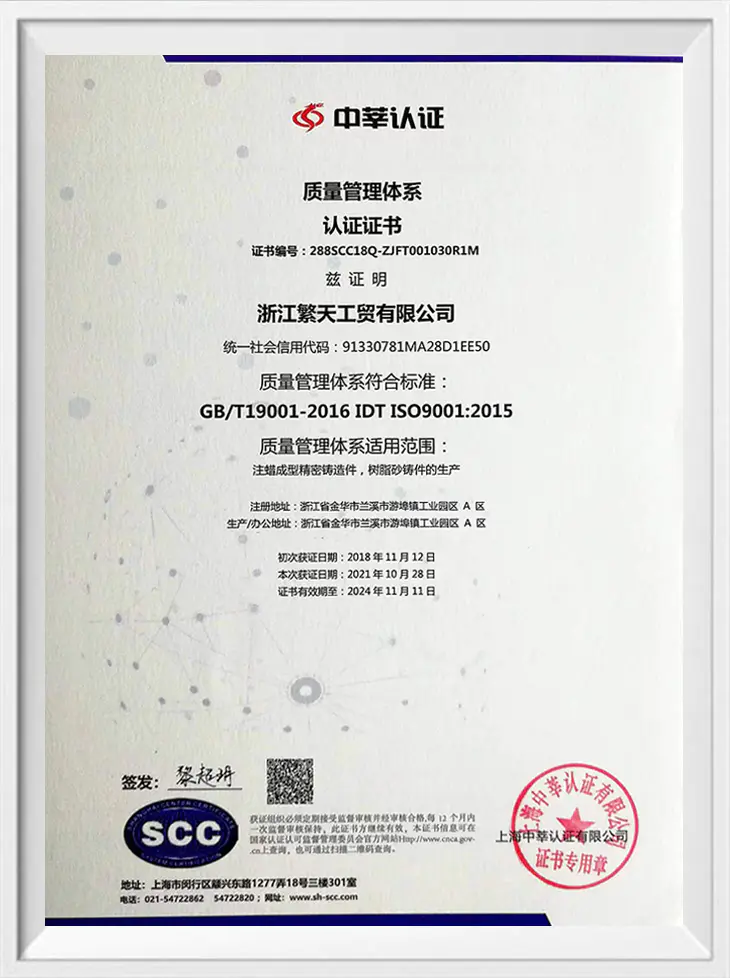

FT CASTING

FT CASTING