Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Automobile&Truck Casting Steel Parts

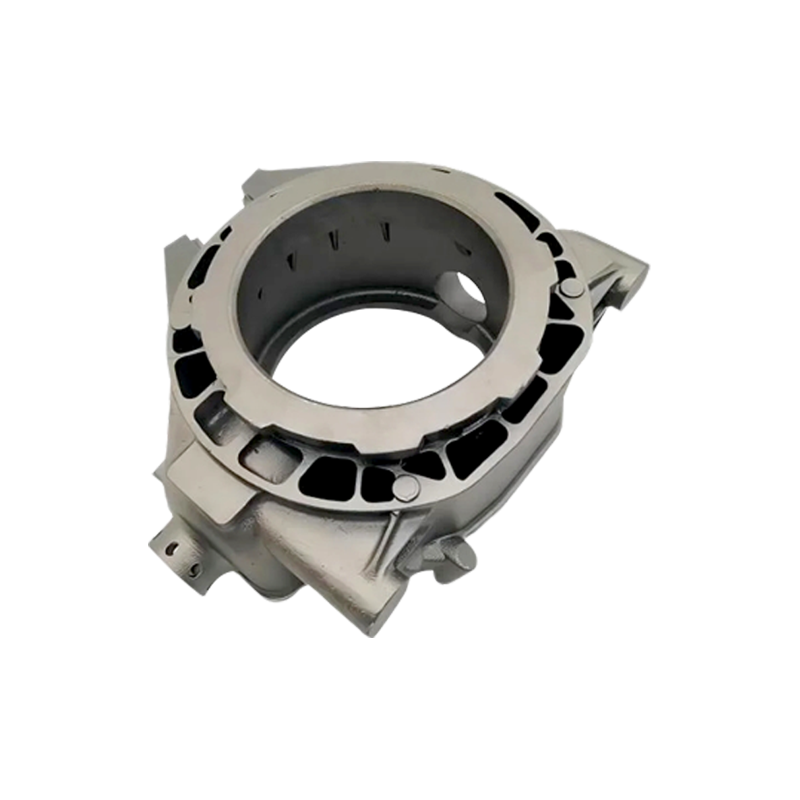

Automobile & Truck Casting Bearing Seat

Bearing seats are cast steel components used to support bearings, secure the outer ring, and ensure stable operation of rotating parts.

Material Characteristics

Cast steel bearing seats are made of cast steel, which features high strength, good toughness, and excellent plasticity. Heat treatment can enhance mechanical properties and corrosion resistance. Compared to other materials (such as gray cast iron), cast steel is more suitable for carrying heavy loads and is commonly used in heavy machinery applications such as metallurgy, chemical engineering, and water conservancy.

Function and Structure

As the outer support for the bearing, the bearing seat secures the outer ring and allows the inner ring to rotate, ensuring stable operation of mechanical components. Depending on the application, the bearing seat can be either integral (non-separable) or split, with designs such as vertical, square, and round.

Applications

Automobile and truck drivetrains (such as wheel axles and engines) are subject to heavy loads. Cast steel bearing seats are preferred due to their high strength and rigidity, especially for maintaining structural stability under bumpy roads and high loads.

Language

Language

FT CASTING

FT CASTING