Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

Ductile iron, often referred to as nodular cast iron, is a type of cast iron that stands out due to its superior mechanical properties when compared to traditional cast iron. Unlike traditional cast iron, which is known for its brittleness, ductile iron combines high strength, toughness, and flexibility, making it a popular material for many industrial applications. This strength and versatility come from the material’s unique microstructure, which can be manipulated through specific alloying elements and heat treatments.

1. Graphite Structure: The Core Difference

One of the primary reasons ductile iron is stronger than traditional cast iron lies in its distinct graphite structure. In traditional cast iron, graphite is formed in the shape of flakes. This flaky graphite structure can lead to stress concentration points, which makes the material brittle and prone to cracking. When subjected to external loads or stresses, these flakes act as stress risers, reducing the material’s overall strength and making it more susceptible to breakage.

In contrast, ductile iron is specifically designed to have graphite in the form of nodules (also referred to as spheroids or spheres). This nodular graphite structure has a significant impact on the material’s mechanical properties. The spherical graphite particles distribute stress more evenly throughout the material, which prevents the formation of cracks. This unique structure allows ductile iron to resist both crack initiation and propagation under stress, resulting in a material that is far tougher and more durable than traditional cast iron.

The nodular graphite structure also allows ductile iron to handle dynamic stresses much better, which is particularly important in applications like automotive parts, machinery components, and infrastructure materials that are exposed to frequent impacts and vibrations.

2. Increased Tensile Strength: Ductile Iron vs. Cast Iron

Another key difference between ductile iron and traditional cast iron is tensile strength. Tensile strength refers to the maximum amount of stress a material can withstand while being stretched or pulled before breaking. Ductile iron has significantly higher tensile strength than traditional cast iron due to the way its graphite is structured and the overall composition of the material.

Traditional cast iron typically has a tensile strength of around 200 to 300 MPa, which limits its use in applications that involve high stress or load-bearing conditions. On the other hand, ductile iron can achieve tensile strengths in the range of 400 to 1200 MPa, depending on the specific alloying elements used and the manufacturing process. This higher tensile strength allows ductile iron to be used in applications where traditional cast iron would fail, such as in structural components, heavy-duty automotive parts, and industrial machinery.

The addition of alloying elements, such as nickel and copper, can further increase the tensile strength of ductile iron, making it suitable for even more demanding applications. This superior strength-to-weight ratio is one of the key reasons why ductile iron is preferred for components that require high performance under stress.

3. Enhanced Ductility: Flexibility Under Stress

As the name suggests, ductile iron is known for its ductility, which refers to its ability to deform under stress without breaking. Traditional cast iron is inherently brittle and will fracture when subjected to tensile stress, making it unsuitable for many applications where flexibility and resilience are needed.

Ductile iron, however, is more flexible and can absorb higher amounts of energy before failure. This is particularly beneficial in applications where parts experience sudden shock loads, vibrations, or bending forces. The combination of high tensile strength and high ductility makes ductile iron an ideal material for components that need to endure harsh working conditions, such as automotive suspension systems, heavy machinery parts, and construction equipment.

Additionally, ductile iron’s ability to deform without cracking helps prevent catastrophic failures in critical applications. This makes it a safer option compared to traditional cast iron, where brittle fractures could lead to sudden and unexpected failures.

4. Superior Impact Resistance

One of the standout features of ductile iron is its impact resistance. Impact resistance refers to a material’s ability to withstand sudden and forceful impacts without cracking or breaking. Due to the spherical graphite structure and the higher ductility of ductile iron, it can absorb more energy from impacts compared to traditional cast iron.

Traditional cast iron, with its flake-like graphite, tends to crack under sudden impact or shock. The presence of these flakes creates internal weaknesses in the material, which can lead to fracture upon impact. In contrast, the nodular graphite structure in ductile iron helps to distribute the force more evenly, allowing the material to absorb and dissipate the impact energy more effectively.

This characteristic makes ductile iron a superior choice for applications where parts are subjected to frequent impacts, such as in the automotive, construction, and heavy machinery industries. For example, engine blocks, brake discs, and gear housings made from ductile iron can resist impacts better than their cast iron counterparts, providing greater reliability and longevity.

5. Alloying Elements and Heat Treatment: Tailoring Mechanical Properties

Ductile iron can be customized to meet specific performance requirements by adjusting its alloying elements and applying heat treatments. Magnesium is a key alloying element in ductile iron, and its addition is critical in transforming the graphite structure from flaky to nodular. This transformation is essential for achieving the material’s enhanced strength, ductility, and impact resistance.

In addition to magnesium, other elements such as nickel, copper, and chromium can be added to ductile iron to further improve its mechanical properties. For instance, nickel enhances the material’s corrosion resistance and toughness, while copper increases its strength and hardness.

Heat treatment processes, such as annealing, tempering, and quenching, can also be used to adjust the properties of ductile iron. These processes help to improve the material’s hardness, wear resistance, and overall strength, making it suitable for a wide range of applications.

6. Better Fatigue Resistance

Fatigue resistance is an essential property for materials that are subjected to repeated loading and unloading cycles. Traditional cast iron tends to fail more quickly under such conditions due to its brittle nature. Ductile iron, with its improved toughness and ductility, exhibits much better fatigue resistance, allowing it to endure more cycles before failure.

This enhanced fatigue resistance is particularly important in parts that are exposed to cyclic loads, such as engine components, suspension parts, and gears. Ductile iron parts can handle repeated stress over a longer lifespan, reducing the need for frequent replacements and repairs.

7. Cost-Effectiveness: Durability and Performance

While ductile iron is generally more expensive to produce than traditional cast iron, its superior performance and durability often lead to a lower total cost of ownership. The increased strength, toughness, and fatigue resistance of ductile iron mean that parts made from this material last longer and perform better over time, even in harsh environments.

Moreover, the improved reliability of ductile iron parts reduces the likelihood of failure and the associated costs of downtime, repairs, and replacements. In many cases, ductile iron provides better value in the long term despite the initial higher material cost.

Applications of Ductile Iron Parts

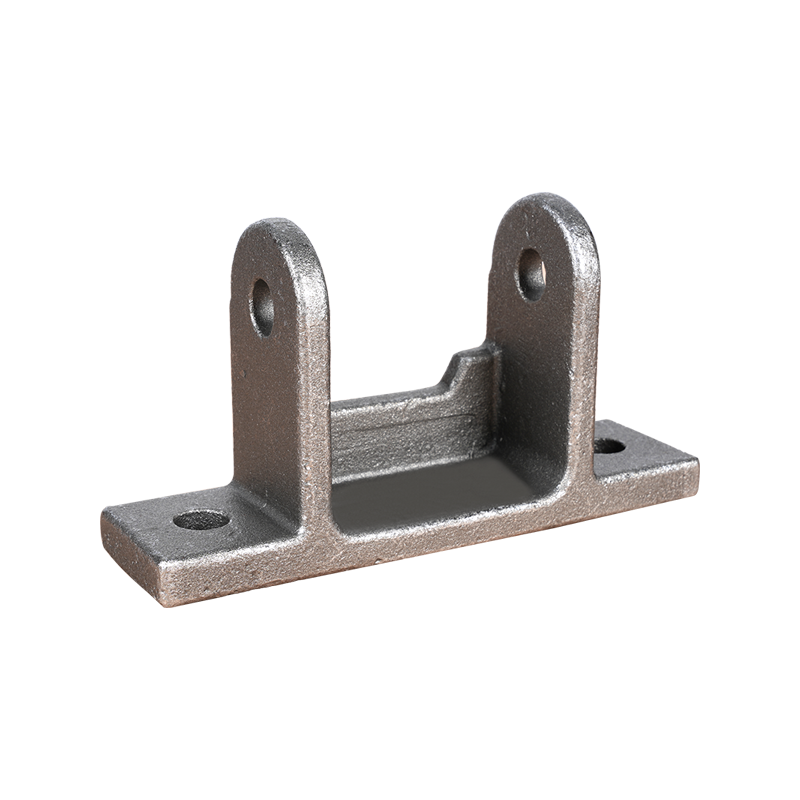

Given its superior strength, ductility, and resistance to impact and fatigue, ductile iron is used in a wide variety of applications across different industries. Some common applications include:

- Automotive Parts: Engine blocks, crankshafts, brake discs, and suspension components.

- Construction Equipment: Hydraulic cylinders, pump housings, and excavator parts.

- Pipe Systems: Water and sewage pipes, as well as fittings.

- Agricultural Machinery: Tractor parts, plow components, and other heavy-duty machinery.

The versatility and strength of ductile iron make it a preferred choice for many high-performance applications that demand both strength and durability.

Language

Language

FT CASTING

FT CASTING