Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Engineering Machinery Casting Steel Parts

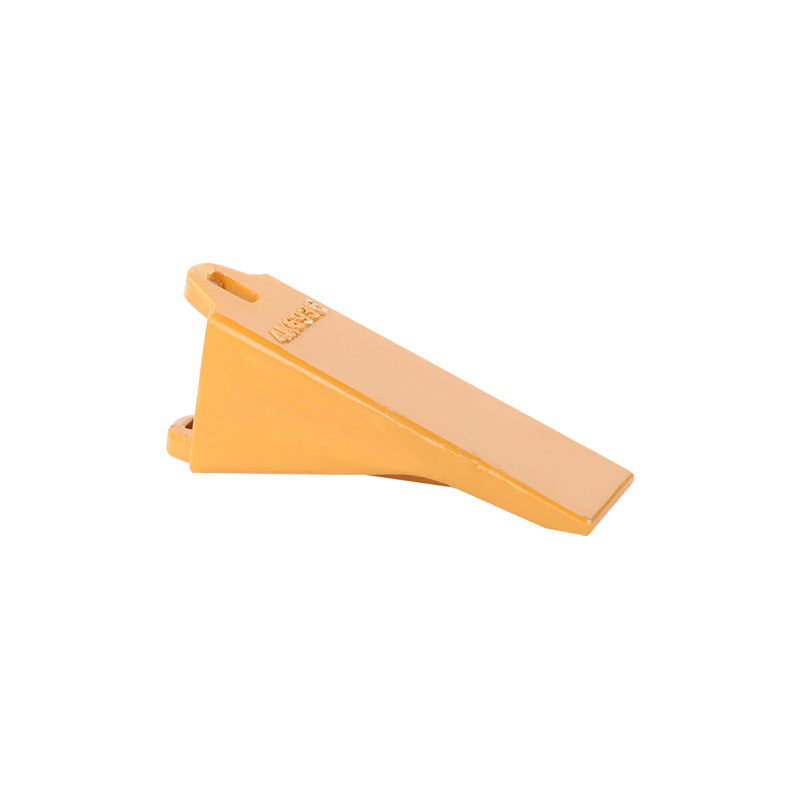

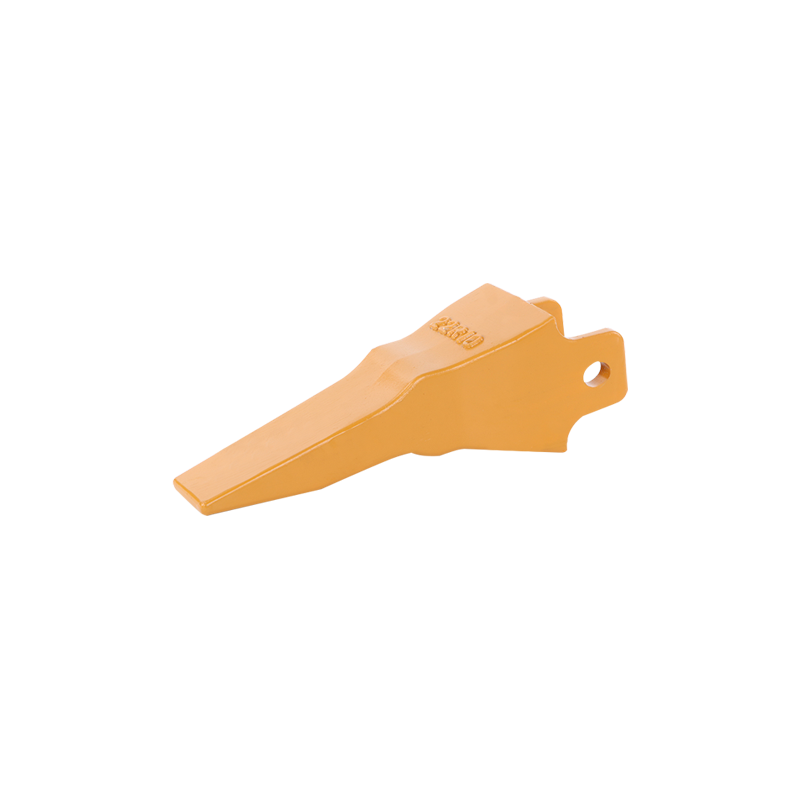

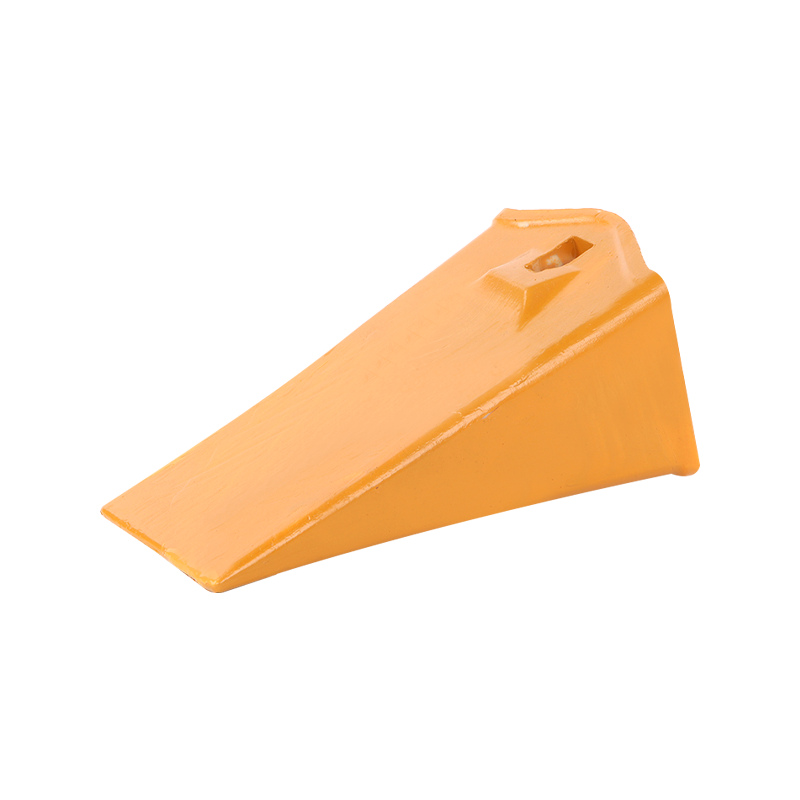

Excavator Bucket Teeth 470-530 HB

Bucket teeth are installed at the front end of the bucket of equipment such as excavators and loaders. They are primarily used for cutting and crushing materials such as soil and rock, and are considered consumable parts.

Structural Features

They typically consist of a tooth adapter and a tooth tip, connected by a pin. The tooth tip directly contacts the material and bears the primary wear. Wear can be replaced individually, reducing maintenance costs.

Material and Application

Material: Typically made of high-manganese steel or alloy structural steel, they offer high strength and wear resistance.

Classifications:

Earthmoving Teeth (Flat Teeth): Suitable for soft materials such as soil, sand, and gravel, with low cutting resistance.

Rock Teeth (RC Teeth): Designed for use in hard rock or coal operations, they offer enhanced wear resistance.

Tapered Teeth (TL Teeth): Commonly found in coal mining operations, they feature a sharper design.

Functions:

Protecting the bucket structure and extending equipment life;

The tooth tip assists with precision work, improving efficiency;

Serves as a cushioning agent when digging hard materials, reducing impact on the equipment.

Language

Language

FT CASTING

FT CASTING