Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Drilling Rig Casting Steel Parts

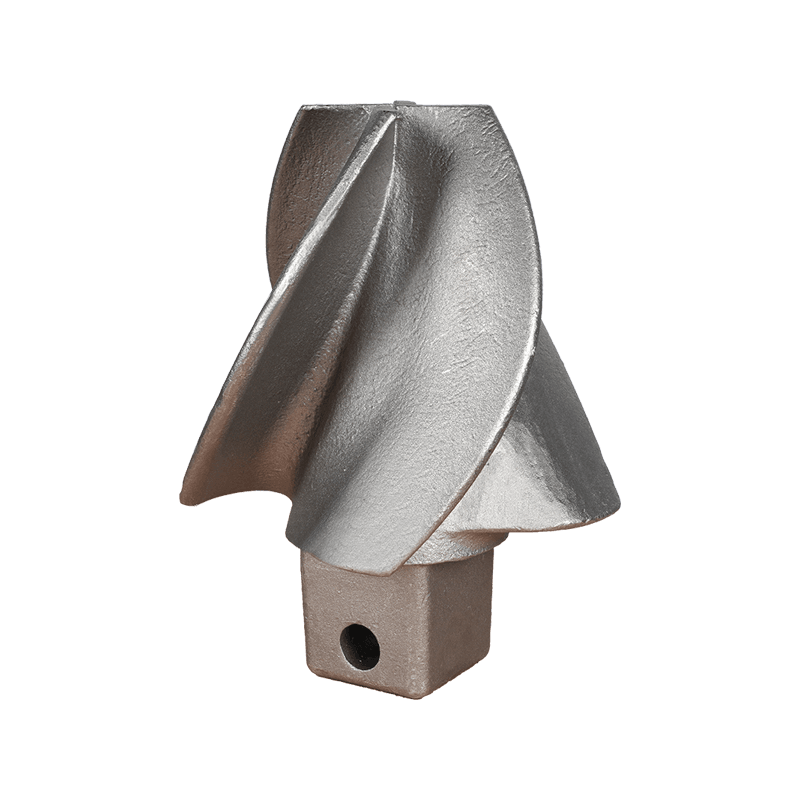

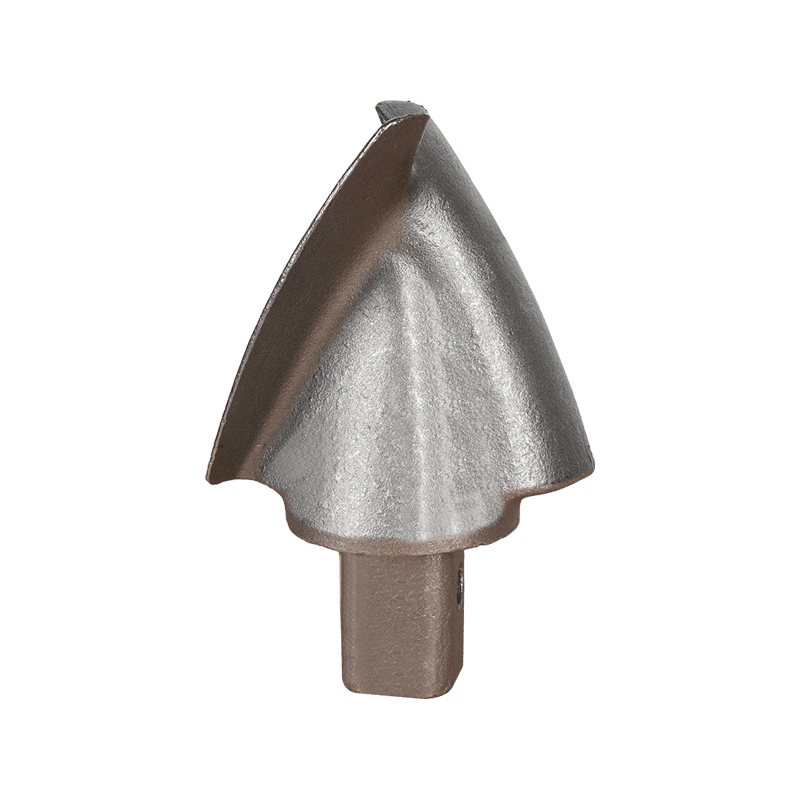

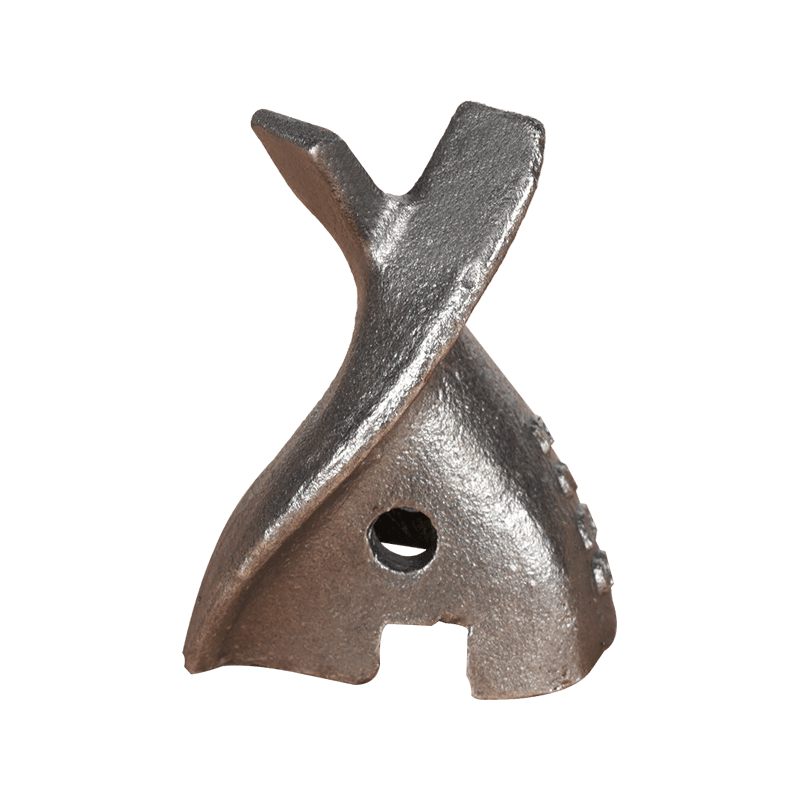

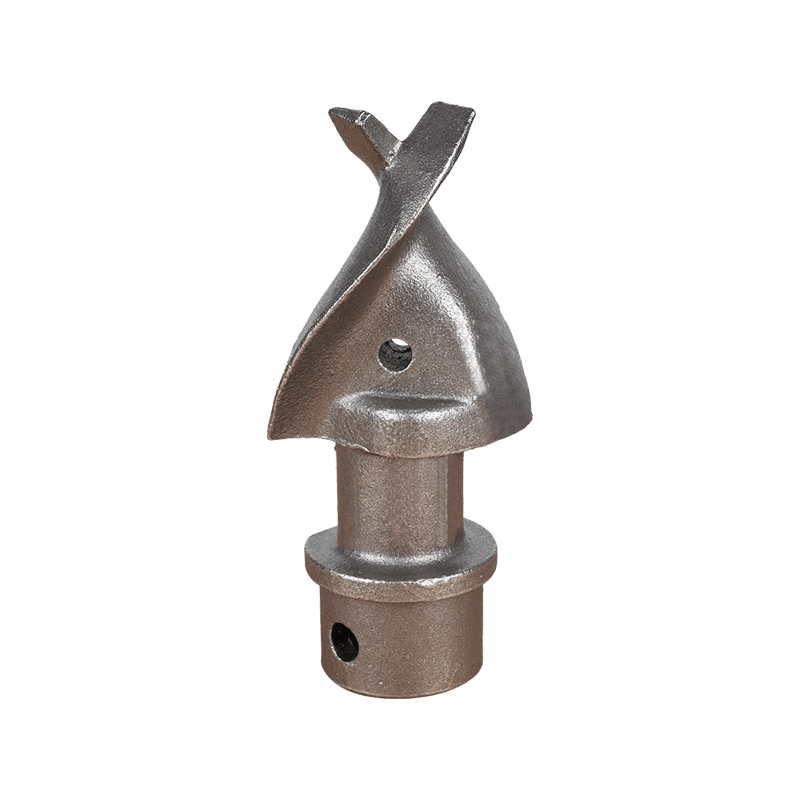

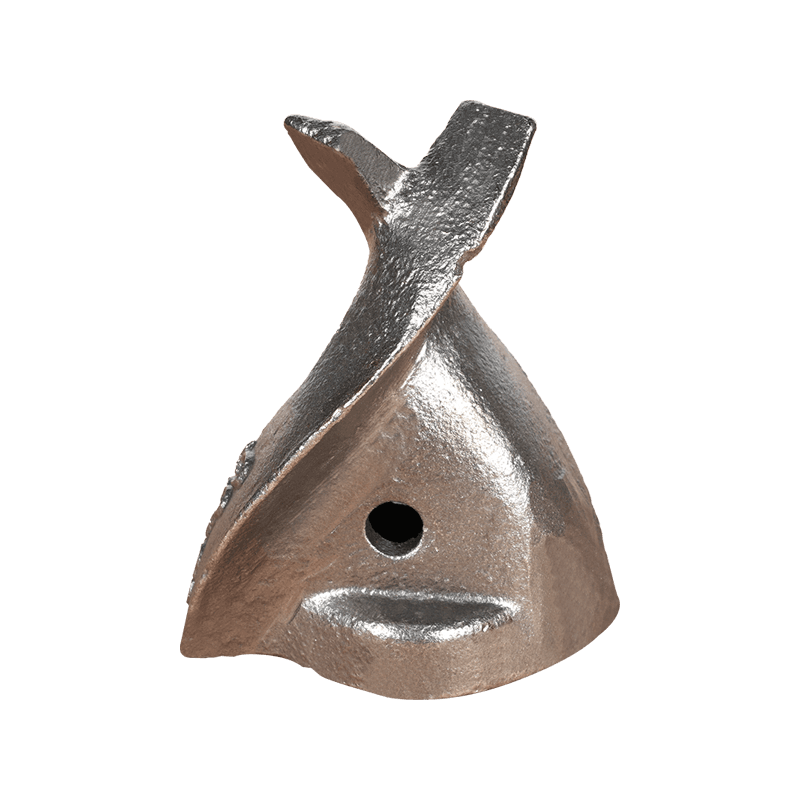

1.9KG Drilling Bits

The small rotary drill bit is a miniature drill bit used with rotary drilling rigs, primarily for small-diameter drilling operations. Its core material is cast steel, offering high strength and wear resistance. It is suitable for soft formations such as clay and silt, or formations containing small amounts of gravel.

Applications

Soft formations: These include clay and silt, offering high drilling efficiency (approximately 5-8 meters/hour).

Small pile operations: Commonly used in applications requiring precise positioning, such as building foundation reinforcement and underground pipeline construction.

Structural Features

Cast steel blades: Improve cutting efficiency and durability.

High-carbon steel drill pipe and flange: Ensure connection strength and deformation resistance.

Selection Recommendations

Preferably, choose a double-ended single-screw or double-ended double-screw design for enhanced slag removal efficiency and stability.

Adjust the drill bit diameter (typically 400-1200mm) based on the formation characteristics to avoid sticking due to oversizing.

Language

Language

FT CASTING

FT CASTING