Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Train Casting Steel Parts

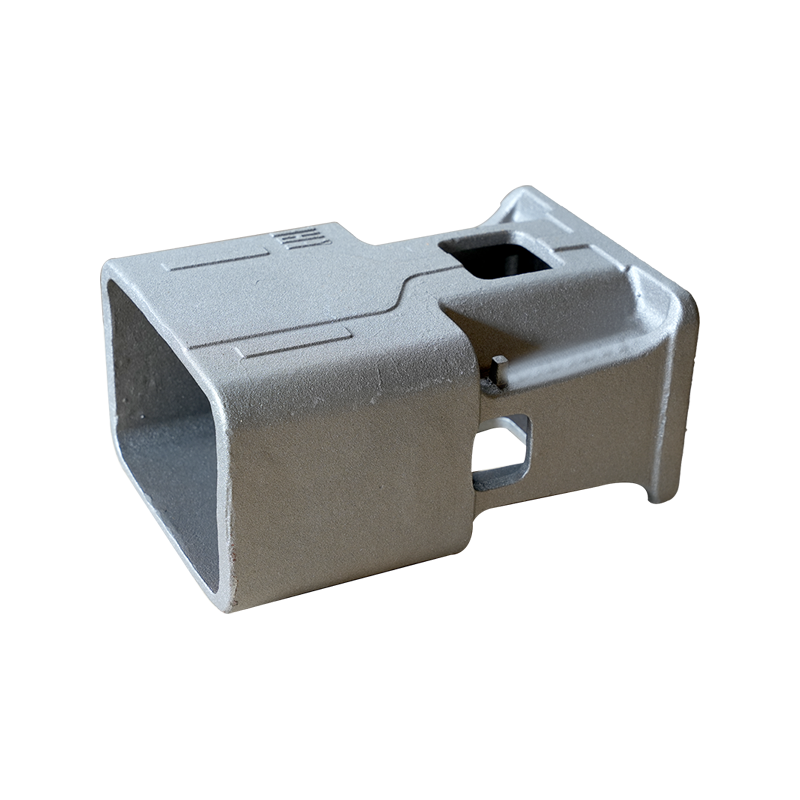

Buffer

Buffers are devices used to mitigate impact forces between train cars during operation and are a crucial component of the coupler system. Their core function is to absorb longitudinal impact forces generated by braking, starting, or shunting operations by compressing elastic elements (such as springs or friction materials), thereby protecting the vehicle structure and cargo.

Structural Composition

Train cast steel buffers typically consist of steel sleeves and powerful spring assemblies, with some models manufactured from cast steel. Installed within the undercarriage traction beam, they work in conjunction with the coupler, coupler yoke, and other components to transmit traction and braking forces and mitigate the impact of collisions between train cars.

Functional Features

Material Properties: Cast steel ensures structural strength and impact resistance, enabling braking conditions equivalent to those of 50 heavily loaded trucks simultaneously.

Energy Absorption: Impact energy is dissipated through spring compression or friction, minimizing damage to the track, vehicles, and cargo.

Regular Inspection: Because functionality cannot be directly tested while the train is operating, it requires periodic disassembly and inspection on a dedicated test bench (e.g., hydraulic testing equipment developed by Swiss Technology Company).

Language

Language

FT CASTING

FT CASTING