Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Engineering Machinery Casting Steel Parts

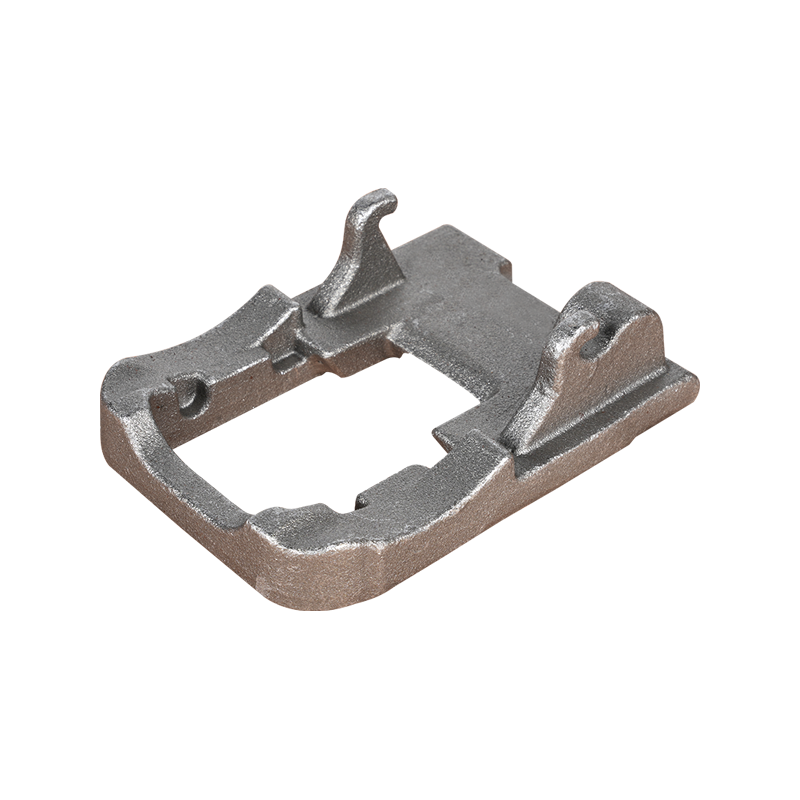

Excavator Connector

An excavator coupler (also known as a quick coupler or quick-change coupling) is a hydraulically controlled device primarily used for quickly attaching and switching between different attachments (such as buckets, breakers, and hydraulic shears) on excavators, significantly improving construction efficiency and expanding the equipment's application range.

Core Function

A hydraulic system controls the locking and release of a pin, enabling rapid replacement of attachments (such as buckets and breakers). This eliminates the need for traditional manual sledgehammer or tool-assisted pin removal, making operation more convenient.

Classification

There are two main types: hydraulic and mechanical. Hydraulic couplers utilize a cylinder to control the movement of a clamp for quick replacement, while mechanical couplers utilize a latch or screw mechanism to lock the pin. Advantages

Improved Efficiency: Traditional replacement takes 40 minutes to an hour, but the quick coupler reduces this to 10 seconds to a minute.

Manpower Savings: Traditional replacement requires two people, while the quick coupler allows a single operator.

Fuel Savings: Traditional replacement consumes 6-8 liters of fuel per change, while the quick coupler consumes only approximately 0.5 liters.

Wide Applicability: Supports the switching of various attachments and requires a low-level working environment (no flat surface required).

Language

Language

FT CASTING

FT CASTING