Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

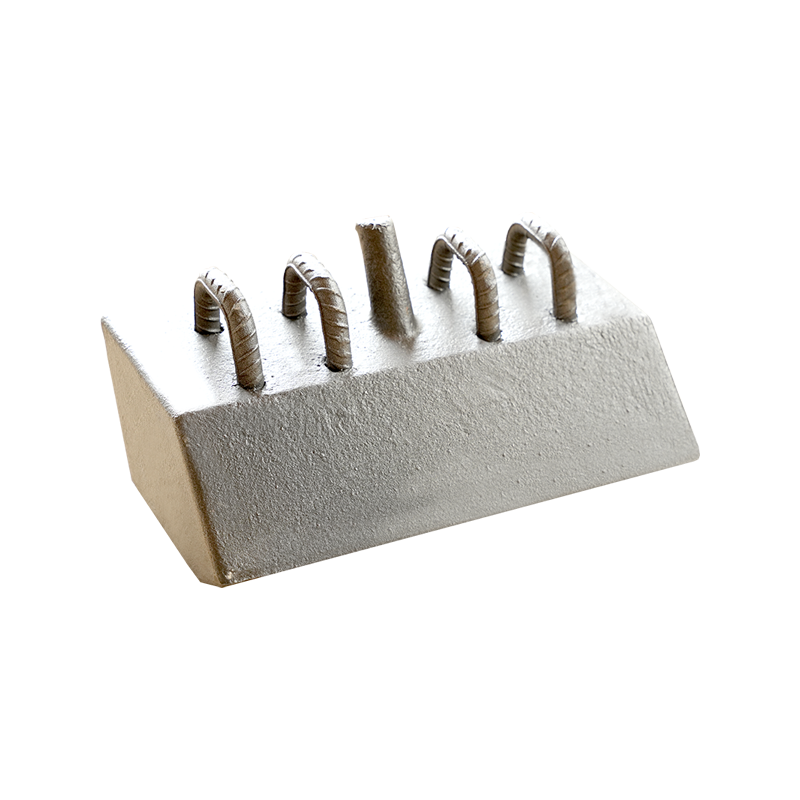

Engineering Machinery Casting Steel Parts

Construction Machinery Parts

Construction machinery accessories refer to various parts and components used in construction machinery (such as excavators and shovels). They fall into two main categories: mechanical accessories and electronic accessories, and are used for power support, operational execution, and drive control.

Definition and Classification of Construction Machinery Accessories

Construction machinery accessories are core components of construction machinery (such as excavators and shovels) and can be categorized into two main categories: mechanical accessories and electronic accessories.

Mechanical accessories:

Provide power support and operational execution functions, including hydraulic pumps, engines, tracks, buckets, cylinders, and working devices (such as booms, shovels, and hammers).

Standard accessories (such as memory and paper feeders) are included with the machine and vary depending on the model. Optional accessories (such as in-vehicle navigation systems) enhance functionality and require additional purchase.

Electronic accessories:

Responsible for drive control and signal feedback, including computer boards, sensors, controllers, hydraulic flow controllers, and other electrical components.

The electronic control system coordinates the operation of mechanical components and monitors operating status in real time to improve efficiency.

The Role and Production of Construction Machinery Parts

Functional Synergy

Mechanical components execute commands, while electronic components provide feedback and adjust operating status. The two work together to improve equipment efficiency.

Production Process

This involves processes such as CNC cutting, casting, welding, and heat treatment, requiring specialized equipment to ensure precision.

Examples of Common Construction Machinery Parts

For excavators, for example, parts include:

Mechanical: bucket teeth, tracks, slewing bearings, hydraulic cylinders, etc.

Electronic: computer boards, angle sensors, diesel meters, fuses, etc.

Language

Language

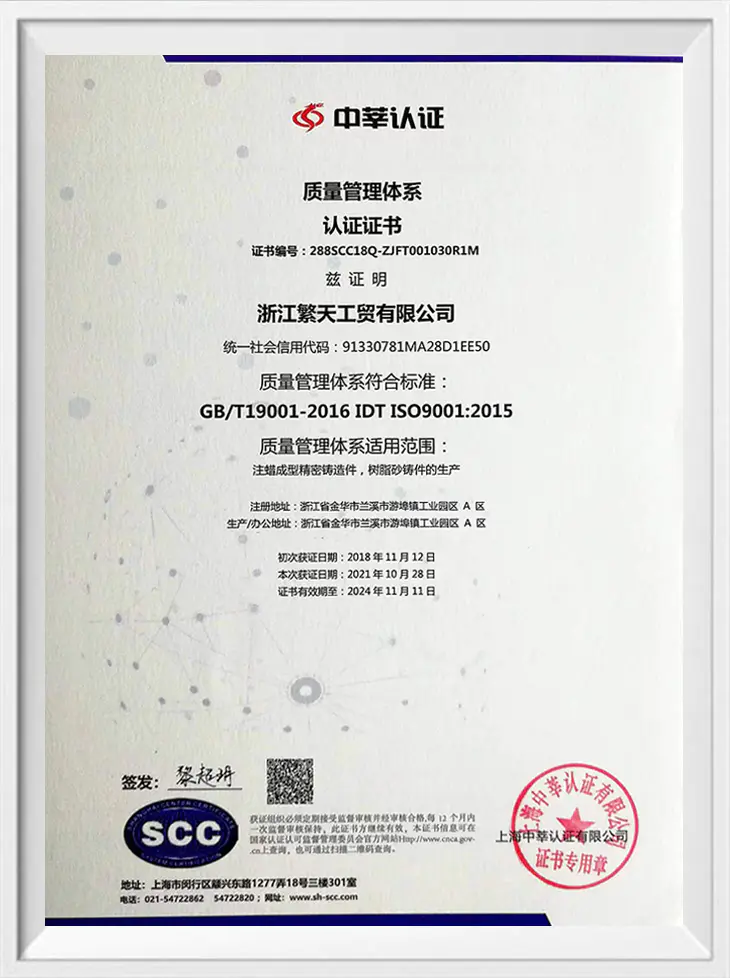

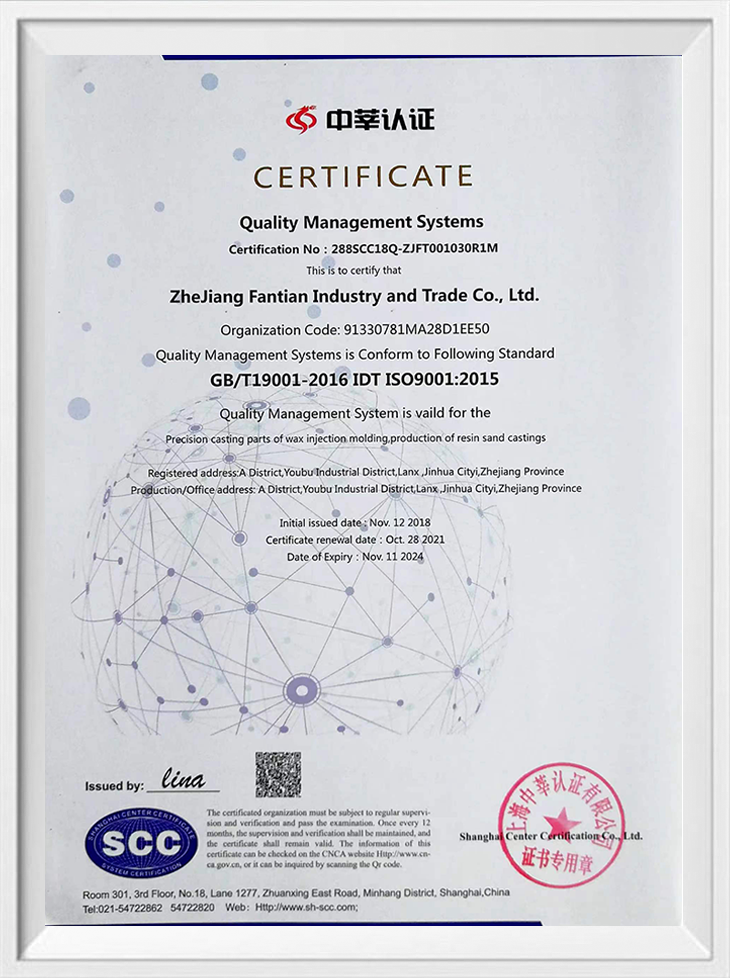

FT CASTING

FT CASTING