Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

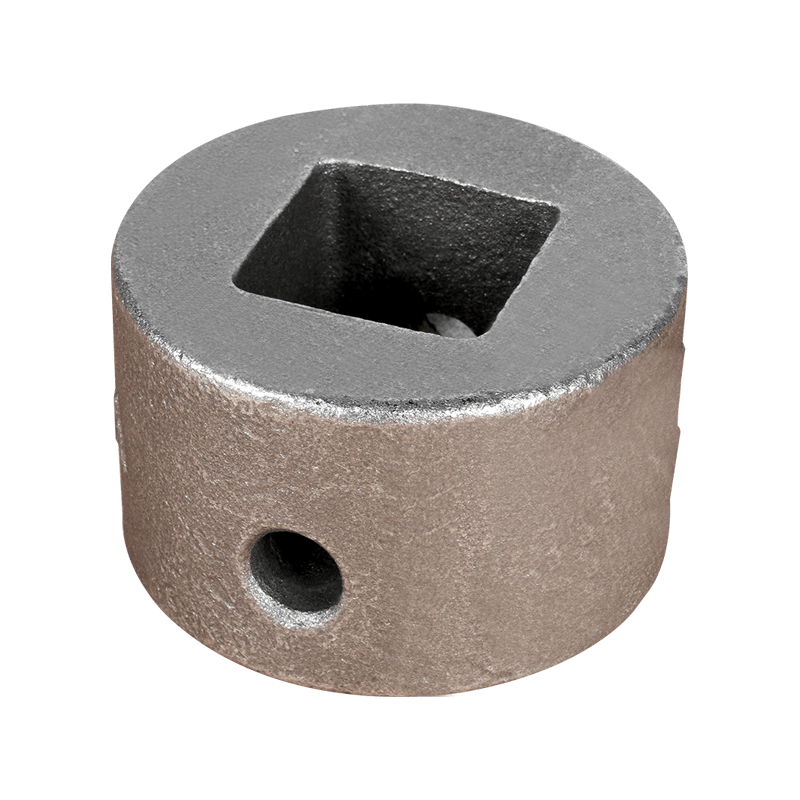

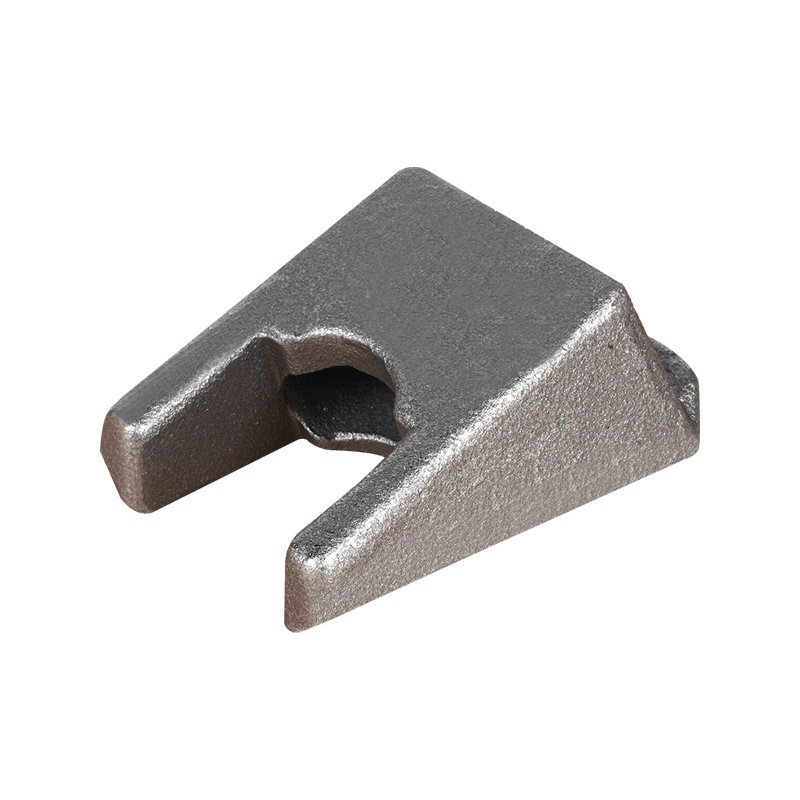

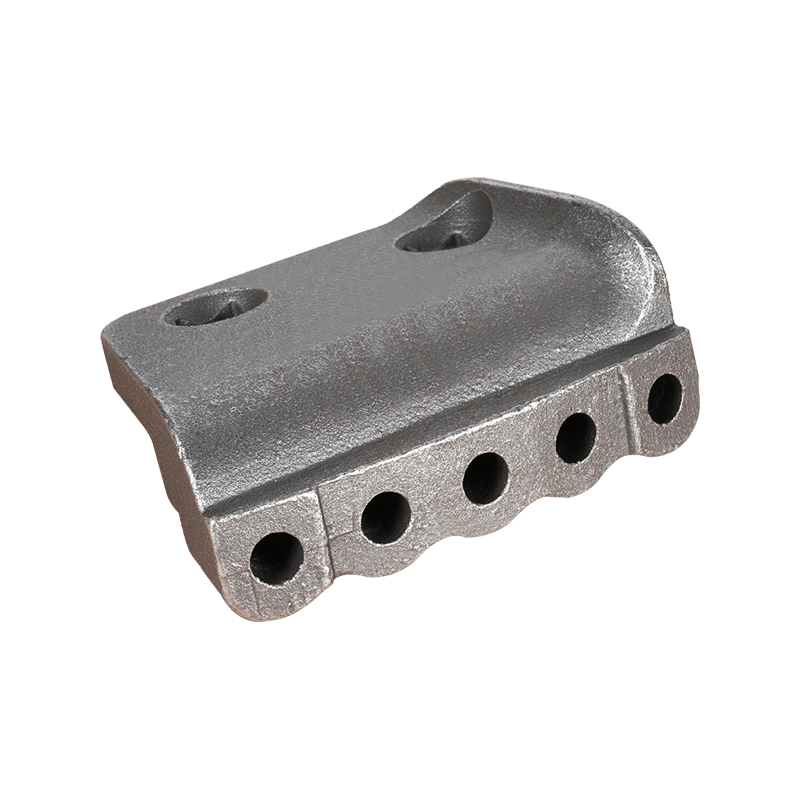

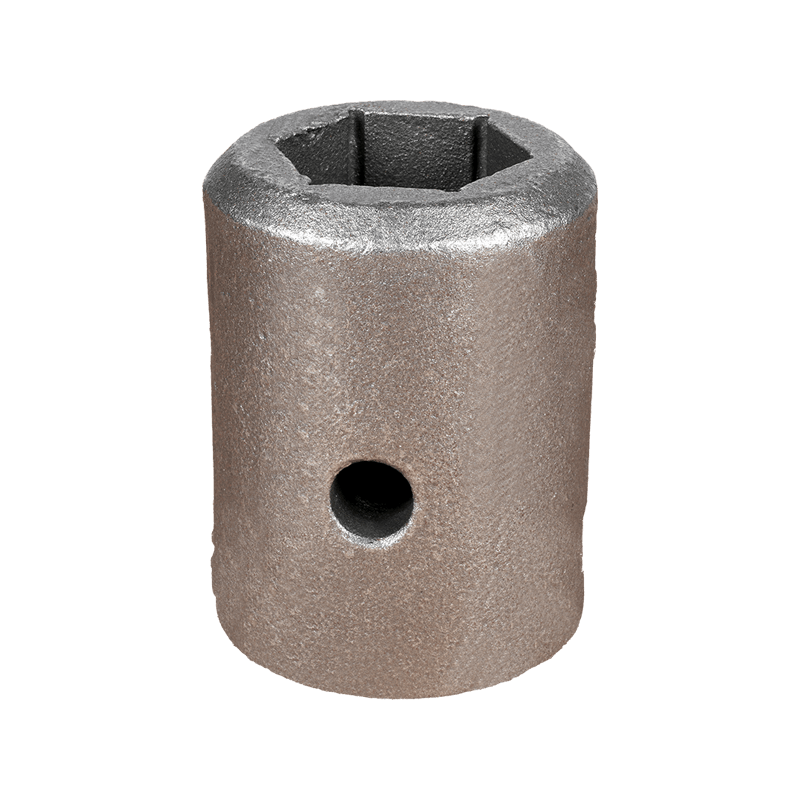

Drilling Rig Casting Steel Parts

Drilling Accessories

Drilling accessories primarily include the following key components:

Drill pipe

Drill pipe is a core component in drilling operations. This threaded steel pipe connects the drilling rig's surface equipment to the bottomhole assembly, transporting drilling fluid, transmitting weight on bit (WOB), and torque, and is reusable. Depending on the required well depth, the drill pipe assembly typically includes different types, such as Kelly and heavy-weight drill pipe.

Drill bit

Drill bits are directly involved in rock breaking. Common types include tri-cone drill bits and diamond-compact drill bits. Diamond-compact drill bits are suitable for hard rock exploration, with 75mm drill bits being a common size.

Hydraulic motor

Hydraulic motors convert hydraulic energy into rotational power, providing continuous and stable driving force for the drill rig. They are characterized by low noise and high efficiency, making them a key power component of the drilling system.

Drilling tools

Drilling tools are used in percussion drilling operations. They consist of a drill bit, drill rod, and other components, breaking rock through impact force and are commonly used in rock drilling operations.

Select the appropriate model for the above accessories based on the specific operating environment to ensure drilling efficiency and safety.

Language

Language

FT CASTING

FT CASTING