Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Automobile&Truck Casting Steel Parts

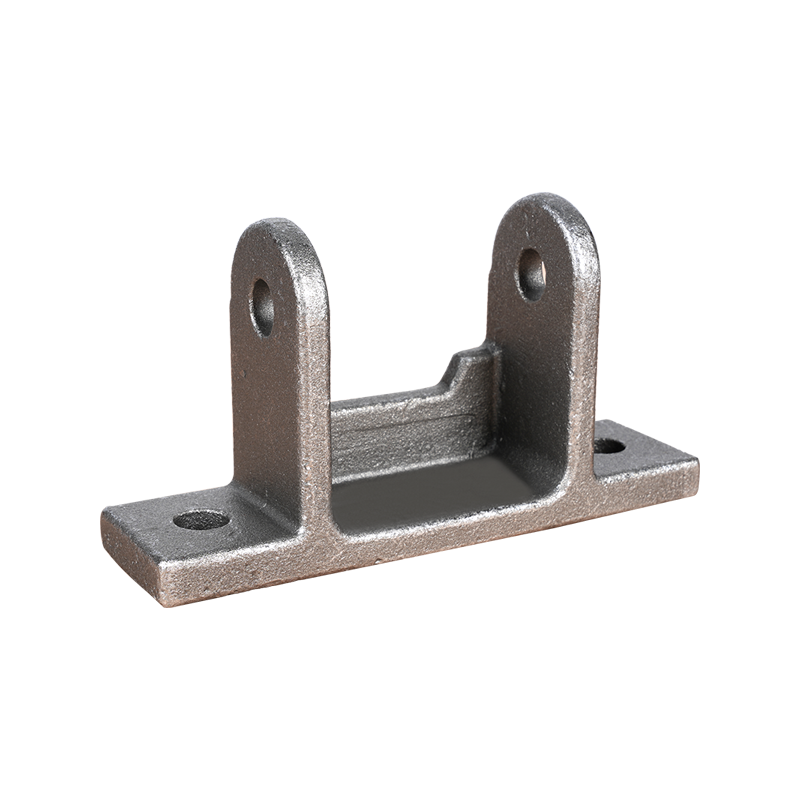

Torsion Bar Bracket

Torsion bar mounts are key components used to support and stabilize the suspension system. Typically made of cast steel or carbon steel, they perform the following functions:

Core Function

Engine/Body Support: They secure the engine or body in place through a rigid structure, reducing vibration and displacement.

Vibration Absorption: Cast steel components disperse and absorb vibrations generated during driving, enhancing driving stability.

Body Stabilization: They work together with the torsion bar to offset body roll, maintaining vehicle balance, especially on rough roads.

Material Characteristics

Common materials are cast steel or carbon steel, which offer high strength, corrosion resistance, and the ability to withstand vehicle weight and dynamic loads for extended periods.

Some torsion bar mounts incorporate rubber damping elements (such as torsion bar rubber) to further reduce vibration transmission.

Structural Features

They typically have a rod or frame structure, mounted on the side of the engine or at key locations on the vehicle frame, securing the suspension components through a rigid connection.

Language

Language

FT CASTING

FT CASTING