Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Automobile&Truck Casting Steel Parts

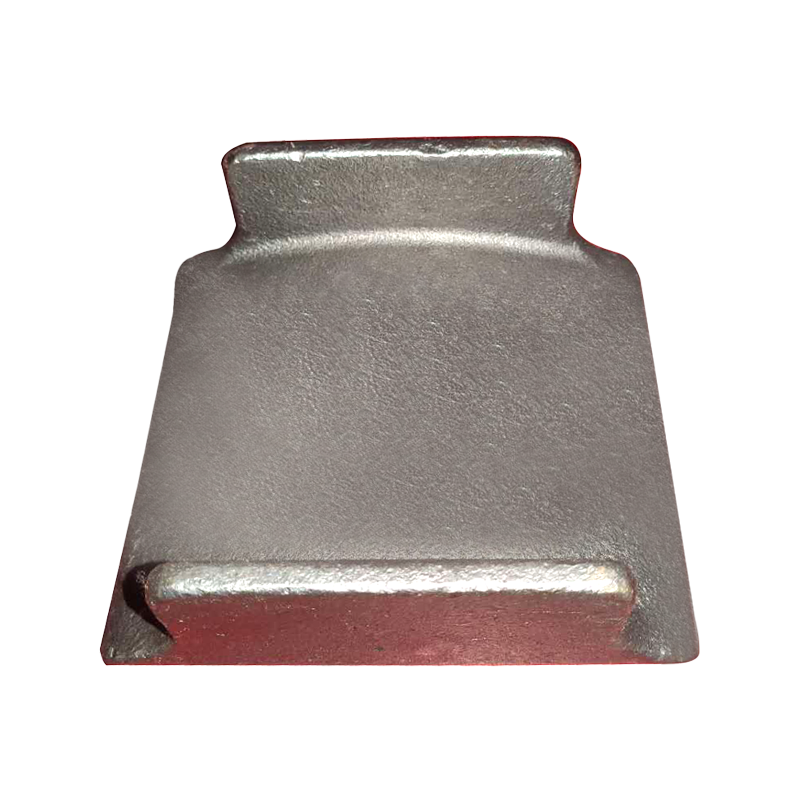

Steel Plate Seat

A "steel plate seat" typically refers to the tractor saddle, a key component connecting the tractor and semi-trailer. Made primarily of wear-resistant steel plate, it features a swinging mechanism to accommodate the impact and vibration of the vehicle's motion.

Structure and Function

The saddle's main body is a horseshoe-shaped wear-resistant steel plate with a semicircular hole notched in the center. It connects to the semi-trailer's drawbar through a locking mechanism. Its structure includes a seat cover, frame, and U-shaped plate. Tie rods, inclined irons, and other components enable detachable and connected saddles.

Material Characteristics

The saddle's steel plate is made of low-carbon or low-alloy steel, often coated with grease to reduce wear. The material must possess high strength and impact resistance to withstand the stresses of vehicle starting, cornering, and braking.

Classification and Application

Saddle #50: Suitable for ordinary road transport trailers, with a drawbar diameter of 50.8mm.

Saddle #90: Suitable for heavy-duty or construction machinery transport trailers, with a drawbar diameter of 90mm. The saddle should be selected to match the vehicle's chassis height and drawbar specifications.

Language

Language

FT CASTING

FT CASTING