Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Agriculture Machine Casting Steel Parts

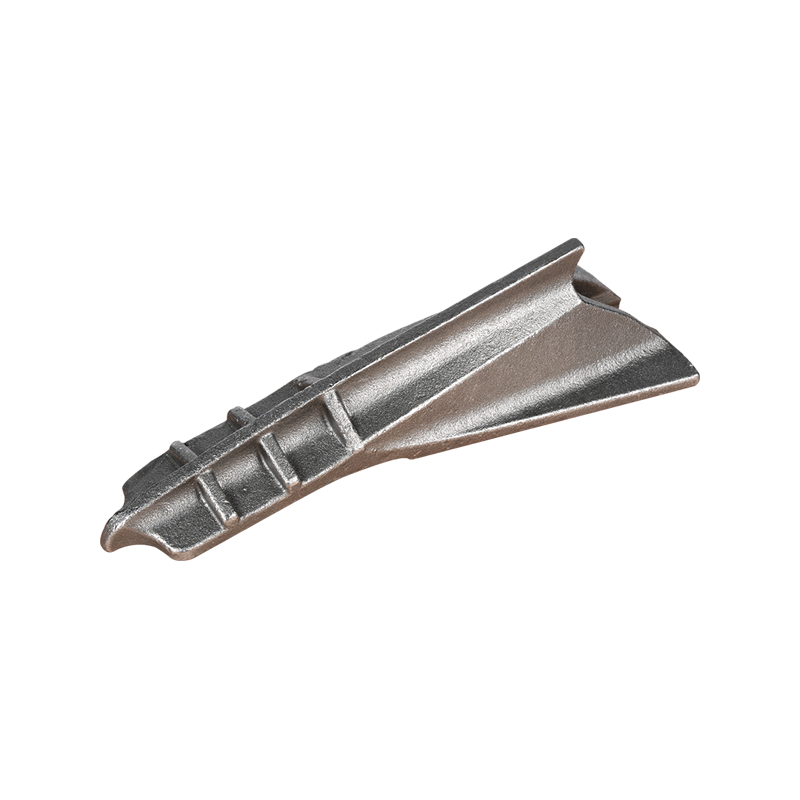

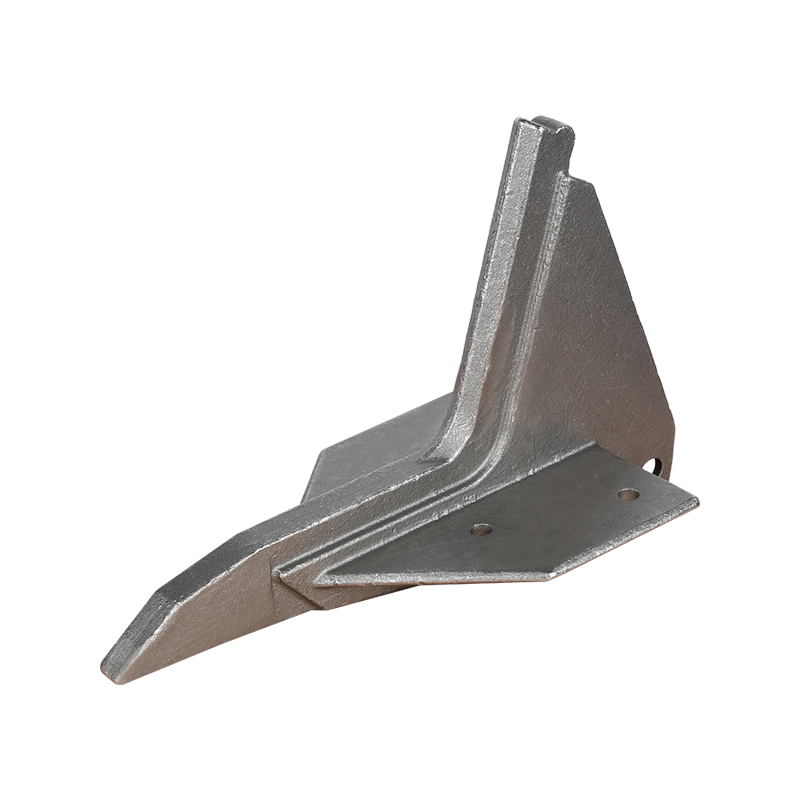

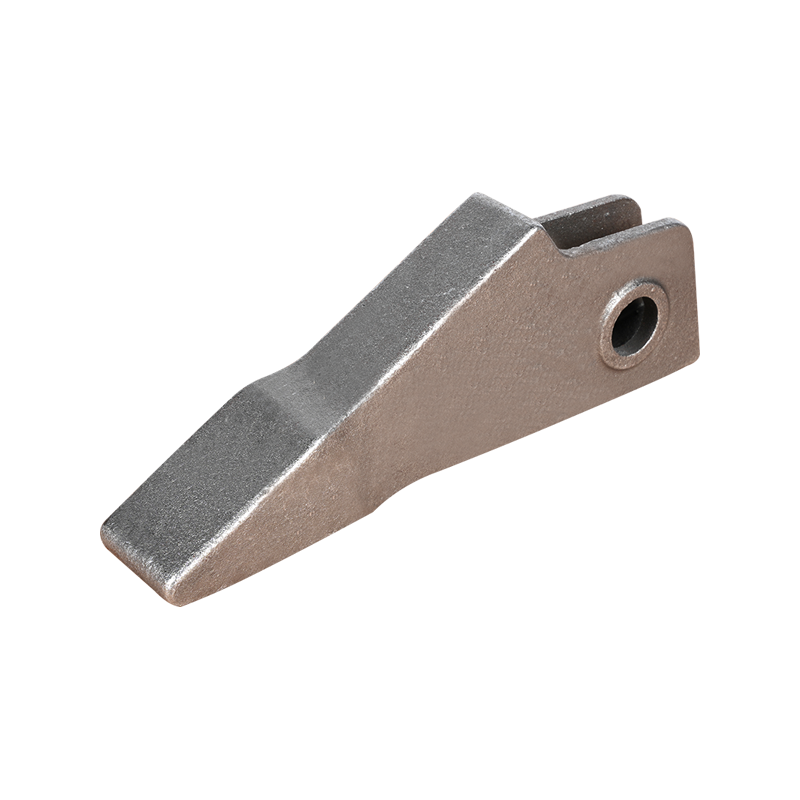

Ploughpoint

The plow point is a key component for tilling the soil. It is typically made of cast steel, offering high wear resistance and durability. The following is a detailed description:

Material and Application

The plow point is made of cast steel (such as alloy steel), which offers high strength and wear resistance, ensuring it remains sharp even during long hours of tilling. Its core function is to cut the soil with its sharp cutting edge, achieving effective tillage.

Technical Features

Wear Resistance: The surface of cast steel components can be treated with special processes (such as hardfacing with a wear-resistant layer) to significantly enhance wear resistance and extend service life. For example, new cast steel plow points, through optimized welding technology, can extend their service life by over 50% compared to traditional components.

Optimized Structure: A sharp cutting edge design and optimal angles ensure easy penetration into the soil, reduce resistance, and improve tillage efficiency.

Suitability: Suitable for various soil types and tillage conditions, with adjustable tillage depth mechanisms, the plow point can be flexibly adapted to suit different farmland needs. Application Scenarios

This product is primarily used in agricultural tillage machinery (such as high-speed plows and moldboard plows). It is widely used in Northeast China and Xinjiang, and is particularly well-suited for complex terrain such as sandy and rocky land.

Language

Language

FT CASTING

FT CASTING