Manufacturing drilling rig casting steel parts is a complex process that involves many challenges. S...

Agriculture Machine Casting Steel Parts

Agricultural Machinery Parts

Agricultural machinery accessories refer to cast steel components used in agricultural machinery, primarily designed to enhance mechanical performance and durability. The following are common types:

Common Accessory Types

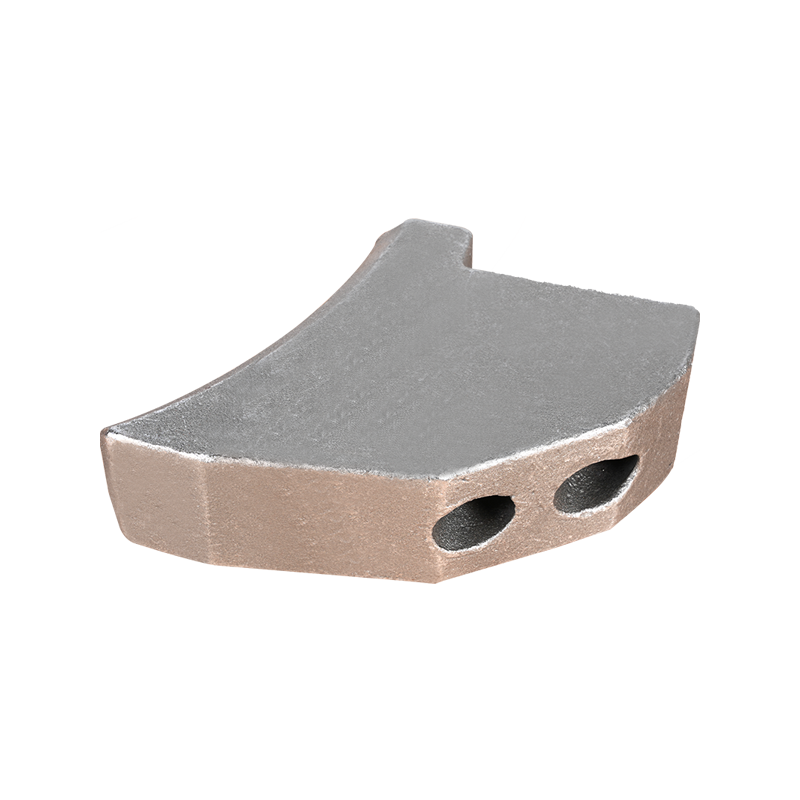

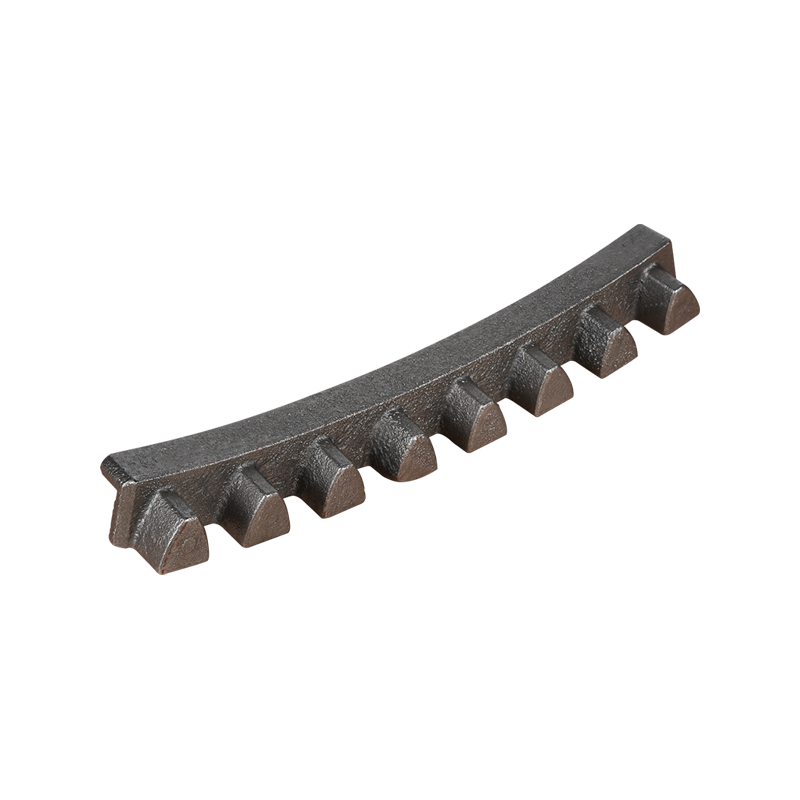

Transmission system components: These include gears, sprockets, and shift forks, used for power transmission and shifting, and require high wear and corrosion resistance.

Structural components: These include brackets, connectors, and support pads, providing support and fixing, and must balance strength and durability.

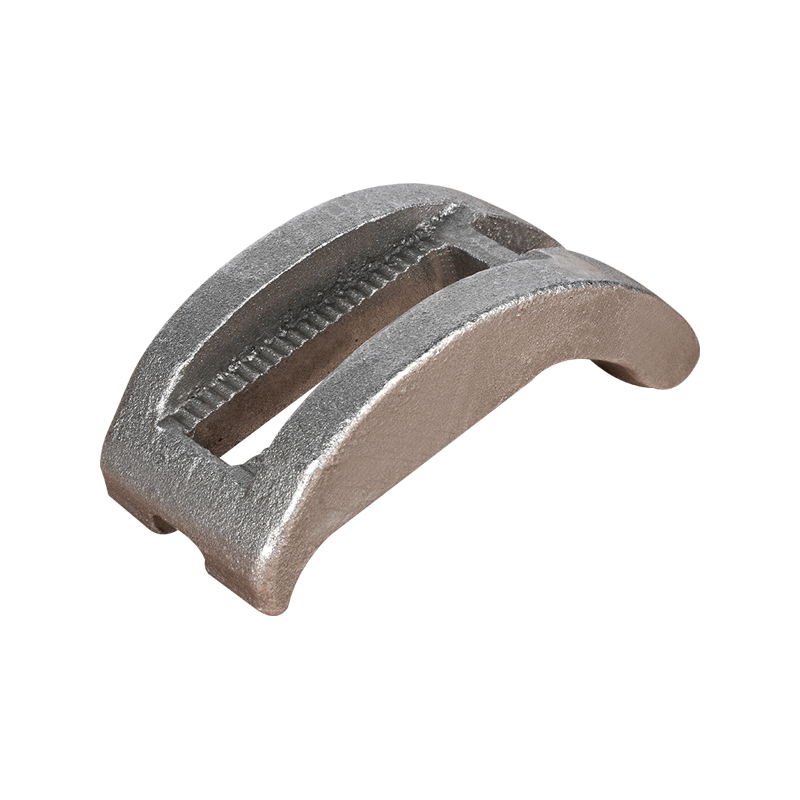

Working components: These include disc blades, notched plow blades, and harvester transfer cases, which are directly involved in operations such as tilling and harvesting, and must adapt to complex working conditions.

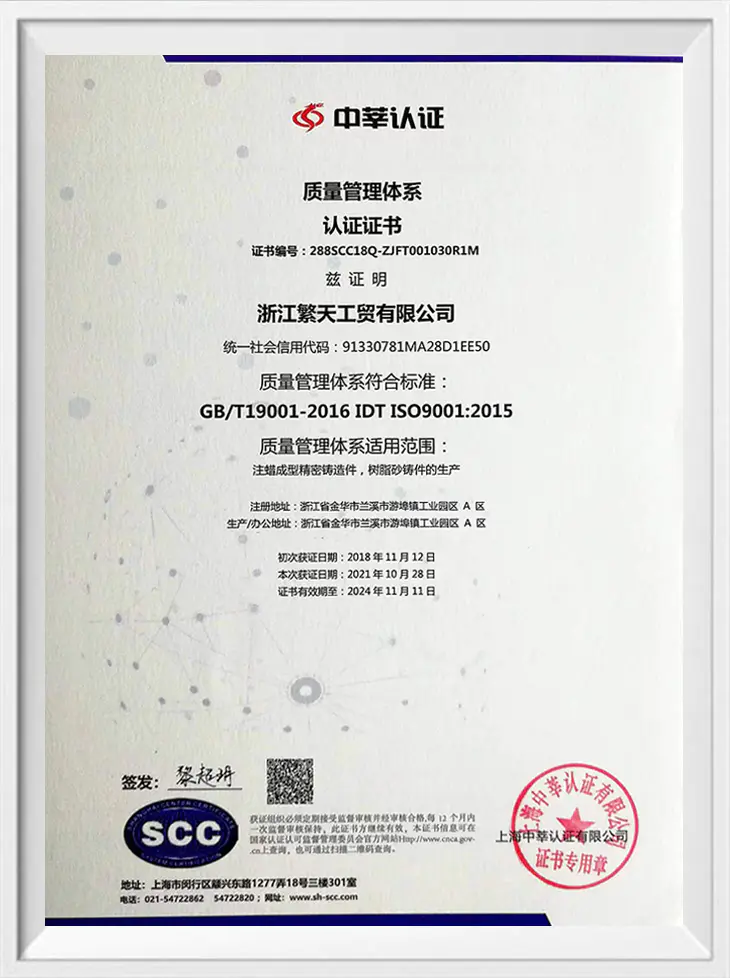

Material Characteristics: Steel castings are often used in the manufacture of key components due to their high strength, wear resistance, and strong resistance to deformation. For example, shift forks utilize precision casting technology to enhance durability, while disc blades utilize cast steel to enhance tillage efficiency and service life. Application Scenarios

This product covers tillage, harvesting, and transportation, including:

Tillage machinery accessories: Disc harrows (400-800mm diameter), notched plow blades, and other tillage components

Powertrain accessories: Gasoline engine pull plates (compatible with 152F-190F models), diesel engine cylinder blocks, and other core components

Harvesting machinery accessories: Corn harvester transfer cases, grain screens (3-8mm aperture), and other specialized components

Language

Language

FT CASTING

FT CASTING