Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

When manufacturing critical components for trains, two prominent techniques used in the production of high-performance parts are steel casting and forging. These two methods each have their strengths and weaknesses, which makes it important to understand their characteristics when choosing the most appropriate method for train components.

1. Overview of Steel Casting and Forging

Steel Casting

Steel casting is the process of pouring molten steel into a mold to form a specific shape. The molten metal is allowed to cool and solidify inside the mold, and once cooled, the casting is removed from the mold to complete the manufacturing process. This method allows for the creation of intricate and complex geometries that might be difficult or impossible to achieve with other manufacturing processes. Steel casting is commonly used to produce large parts that require precision and consistency.

Forging

Forging is a process in which metal is shaped by applying compressive forces. These forces can be applied either through hammering, pressing, or rolling. In the forging process, the metal is usually heated to high temperatures before being worked on. This ensures the material remains malleable and can be shaped effectively. The result is a component with superior grain structure and strength due to the alignment of the metal’s crystalline structure.

2. Material Properties

Steel Casting

Steel casting typically results in a material that is capable of producing parts with complex designs and dimensional accuracy. However, there are some trade-offs in terms of the mechanical properties of cast steel. Cast components often exhibit lower strength and fatigue resistance compared to forged components due to the way the metal solidifies. The grain structure in cast parts is less uniform, which can lead to weak spots in certain areas.

While casting does allow for intricate shapes, it does not always provide the same material properties as forging. Cast components are generally more prone to issues like porosity (air pockets) and inclusions (foreign material), which can reduce the overall strength and reliability of the part.

Forging

Forging, on the other hand, results in parts with superior mechanical properties. The compressive forces used during the forging process realign the metal’s grain structure, making the material denser and stronger. This is particularly beneficial for parts that will experience heavy loads, as forged components are known for their toughness, fatigue resistance, and overall durability. The continuous grain flow created during forging enhances the material’s resistance to fracture, ensuring better performance under stress.

Forged parts tend to outperform cast parts when it comes to high-stress applications, such as train wheels and axles, because the grain structure in forged components is much more homogeneous.

3. Cost Efficiency

Steel Casting

One of the primary benefits of steel casting is its cost-effectiveness, particularly for large runs of parts with complex geometries. The initial tooling and mold costs can be significant, but once the molds are created, the cost per part decreases substantially as production volumes increase. This makes casting an economical choice for manufacturing large numbers of parts, especially when the complexity of the part justifies the use of a casting process.

Additionally, casting allows for the production of large parts in one piece, reducing the need for additional machining or welding, which can further reduce costs. For less critical parts that do not require the highest strength or fatigue resistance, casting is often the more cost-effective option.

Forging

Forging generally comes with higher upfront costs due to the energy-intensive process involved. The material must be heated to high temperatures before it can be shaped, which requires considerable energy. Furthermore, the machinery and tooling used for forging—such as presses, hammers, and furnaces—are expensive. These factors contribute to higher production costs compared to casting.

Moreover, the forging process is more time-consuming than casting. Forged components typically take longer to produce due to the need for repeated forging cycles and cooling times. For smaller production runs or highly specialized components, these extra costs can be justified by the superior strength and durability of the final part. However, for large volumes of less demanding parts, forging may not be the most cost-effective method.

4. Precision and Complexity

Steel Casting

Steel casting allows manufacturers to create parts with highly intricate designs and complex shapes that would be difficult or impossible to achieve using other methods. This is particularly valuable for applications where the part needs to have internal cavities, undercuts, or other specialized features. Steel casting is often used in the production of parts such as engine blocks, transmission housings, and other complex components in the railway industry.

While steel casting offers exceptional flexibility in terms of part design, it often requires additional post-processing, such as machining or grinding, to achieve the final desired dimensions and surface finish. This can add to the overall cost of the part, but the benefits of producing complex components in a single step often outweigh the extra effort required.

Forging

Forging is best suited for components that have relatively simple shapes and designs. While forged parts can be made to precise specifications, they are generally limited to certain types of geometries that are easier to form under compressive forces. Forging excels when the part’s strength and durability are the most important factors, but it may not be the best choice for parts that require complex internal features or intricate shapes.

The process of forging limits the types of components that can be made compared to casting. Parts such as train wheels and axles are perfect candidates for forging, but more complicated parts with internal cavities or features would be better suited for casting.

5. Applications in Train Components

Steel Casting

Steel casting is used extensively in the railway industry for components that require complex shapes and are not subjected to extreme stresses. Some of the most common applications for steel casting in train manufacturing include:

- Train Frame Parts: Steel casting is ideal for creating large structural parts, such as the frame or chassis of a train. These parts need to be robust but can be produced in large quantities at a relatively low cost.

- Brake Systems: Components such as brake housings or brake drums, which need to have both strength and shape flexibility, are commonly made using casting.

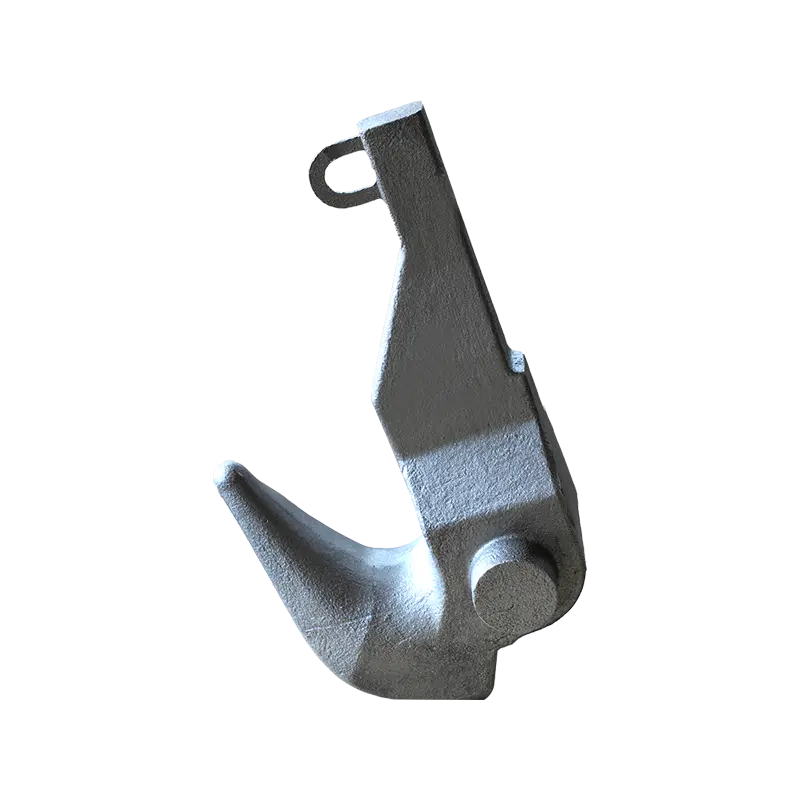

- Couplings and Connecting Parts: Cast steel is often used to make couplings and other components that require precision but do not experience extreme stress or fatigue.

Forging

Forging is primarily used for high-strength, high-durability components in the railway sector. The following are some examples of train parts that benefit from forging:

- Train Wheels: Train wheels are subject to extreme loads and stresses. The forging process enhances the material’s strength, making it ideal for components that will bear weight and impact.

- Axles: Forged axles are preferred due to their superior strength and fatigue resistance. These parts are subjected to repetitive stress and need to maintain their integrity over long periods of operation.

- Connecting Rods and Crankshafts: Forged components are often used in train engines for parts that need to withstand high levels of stress and mechanical loading.

6. Strength and Durability

Steel Casting

While steel casting provides good strength, especially for large components, it does not offer the same level of durability or fatigue resistance as forged parts. Cast components are often more prone to cracking, deformation, and wear over time, especially under heavy or repetitive loads. For critical applications, cast components require more frequent inspections and maintenance to ensure their integrity.

Forging

Forged components, on the other hand, excel in terms of strength, toughness, and durability. The grain structure of forged parts is far superior, making them much more resistant to fatigue, wear, and failure under stress. Forging is particularly beneficial for parts that will experience extreme conditions, such as axles, train wheels, and engine components. The improved mechanical properties of forged parts ensure they have a longer service life, reducing the need for frequent repairs or replacements.

7. Maintenance and Reliability

Steel Casting

Cast parts may be more susceptible to defects such as cracks, voids, and inclusions, which can reduce their long-term reliability. These defects can compromise the component’s integrity, leading to a higher likelihood of failure or the need for frequent maintenance. As a result, regular inspections are necessary to ensure the reliability of cast components in critical applications.

Forging

Forged components are generally more reliable due to their stronger, more uniform grain structure. The alignment of grains during the forging process makes these parts much more resistant to cracking and fatigue, leading to longer service life and reduced maintenance needs. Forged parts are less likely to fail under extreme stress and are typically more dependable in high-load applications.

Comparison of Steel Casting vs. Forging for Train Components

| Feature | Steel Casting | Forging |

|---|---|---|

| Cost | More cost-effective for large runs and complex parts | More expensive due to higher energy and tooling costs |

| Strength | Lower strength compared to forging | Superior strength due to grain alignment |

| **Dur |

Language

Language

FT CASTING

FT CASTING