Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

Introduction

Automobiles and trucks rely heavily on strong and reliable components to ensure durability, safety, and cost efficiency. Among the most widely used manufacturing methods for critical parts are Casting Steel Parts and Forged Steel Parts. Both processes have unique advantages and limitations, making them suitable for different applications within the automotive and truck industries.

What Are Casting Steel Parts?

Definition and Process

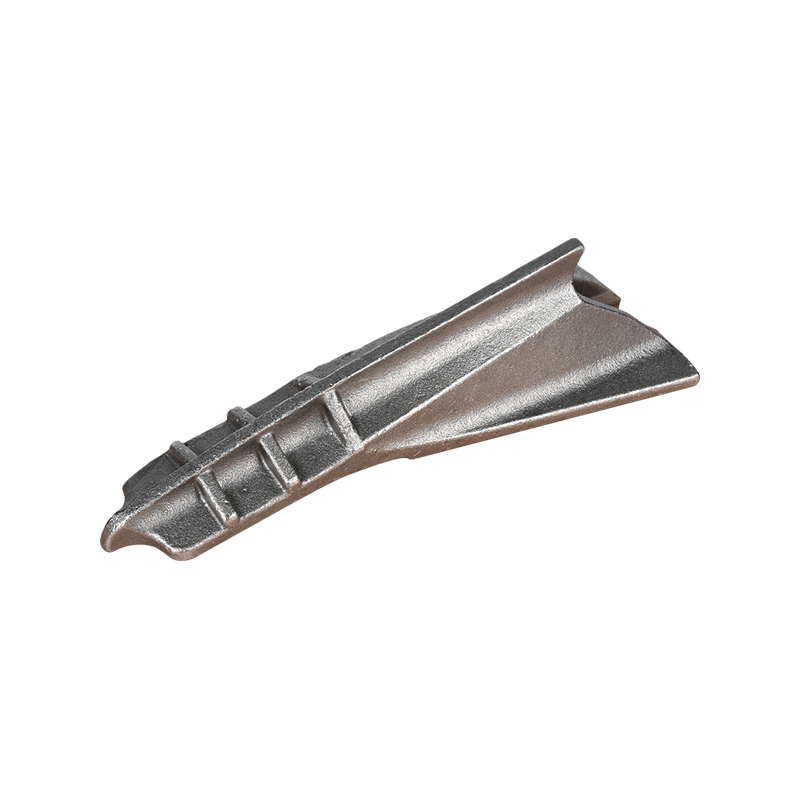

Casting steel parts are produced by pouring molten steel into a mold, allowing it to cool and solidify into the desired shape. Common casting methods include sand casting, investment casting, and die casting. This process is widely used because it can produce complex geometries that would be difficult or impossible to achieve with forging.

Applications in Automobiles and Trucks

Casting is frequently used for engine brackets, suspension components, differential housings, and gearboxes. For heavy-duty trucks, casting is especially useful for large and intricate components that require mass production.

Advantages of Casting Steel Parts

- Ability to produce complex shapes and designs

- Cost-effective for large-scale production

- Lower material waste compared to forging

- Flexibility in design modifications

Limitations of Casting Steel Parts

- Mechanical properties are generally lower than forged parts

- Possible defects such as porosity, shrinkage, or cracks

- Not ideal for components under extremely high stress

What Are Forged Steel Parts?

Definition and Process

Forged steel parts are manufactured by applying compressive forces to steel billets or ingots, shaping them into the required form. Forging methods include open-die forging, closed-die forging, and cold forging. The forging process aligns the grain structure of the steel, which enhances its strength and toughness.

Applications in Automobiles and Trucks

Forging is the preferred choice for critical components such as crankshafts, steering arms, connecting rods, and heavy-duty axles. Trucks that carry high loads often rely on forged parts for safety and performance.

Advantages of Forged Steel Parts

- Superior strength and toughness

- Better resistance to fatigue and impact loads

- Excellent performance in high-stress applications

- Longer lifespan compared to cast parts

Limitations of Forged Steel Parts

- Higher production cost

- Limited ability to create complex geometries

- Requires additional machining after forging

Performance Comparison: Casting vs Forging

To understand the differences between casting steel parts and forged steel parts, it is helpful to look at their performance side by side:

| Criteria | Casting Steel Parts | Forged Steel Parts |

|---|---|---|

| Strength | Moderate, may contain defects | High, with superior grain structure |

| Complexity | Can produce very complex shapes | Limited to simpler shapes |

| Cost | Lower initial cost, good for mass production | Higher cost, but longer lifespan |

| Applications | Engine housings, brackets, suspension parts | Crankshafts, axles, steering arms |

| Durability | Good, but may fail under high stress | Excellent, suitable for heavy-duty use |

Applications in Automobiles and Trucks

Automobiles

In passenger cars, casting steel parts are often used for components that require complex shapes but moderate strength, such as gearboxes, engine blocks, and suspension mounts. On the other hand, forged steel parts are used in high-stress areas like crankshafts, connecting rods, and steering knuckles.

Trucks

For heavy-duty trucks, durability and load capacity are critical. Forged steel parts are typically used in the drivetrain, suspension, and chassis where maximum strength is needed. Casting steel parts are applied in less critical areas such as housings and brackets, where shape complexity is more important than absolute strength.

How to Choose Between Casting and Forging?

The choice between casting steel parts and forged steel parts depends on multiple factors:

- Strength and durability: Forging is superior for heavy-duty and high-stress components.

- Complexity and design flexibility: Casting is better for intricate designs.

- Cost considerations: Casting offers lower upfront costs, while forging ensures longer part life.

- Application type: Automobiles may benefit from both, while trucks often rely more on forging.

Language

Language

FT CASTING

FT CASTING