Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

1. Improved Durability and Strength

Train Casting Steel Parts offer superior strength and durability, essential for withstanding the high pressures and stresses encountered during high-speed travel. These materials are robust enough to handle the extreme mechanical forces, reducing wear and tear on key components such as wheels, axles, and frame structures. Steel’s ability to resist fatigue, cracks, and corrosion extends the lifespan of critical train components, ensuring long-term operational reliability.

2. Weight Reduction Without Compromising Strength

One of the primary challenges in designing high-speed trains is minimizing weight while maintaining strength and safety. Steel casting provides a solution by allowing for the creation of lightweight yet strong components. Innovations in casting techniques, such as the use of high-strength low-alloy (HSLA) steel, have helped manufacturers reduce the overall weight of parts without compromising their load-bearing capabilities, which improves fuel efficiency and speed.

3. Enhanced Safety Features

Safety is paramount in high-speed rail systems. Casting steel parts contribute significantly to this by providing robust crash-resistance features. For instance, steel is used in critical areas such as the train's frame, undercarriage, and braking system, ensuring the integrity of the structure even under extreme conditions. The material’s ability to absorb and dissipate energy during a collision can help mitigate damage and protect passengers.

4. Precision and Design Flexibility

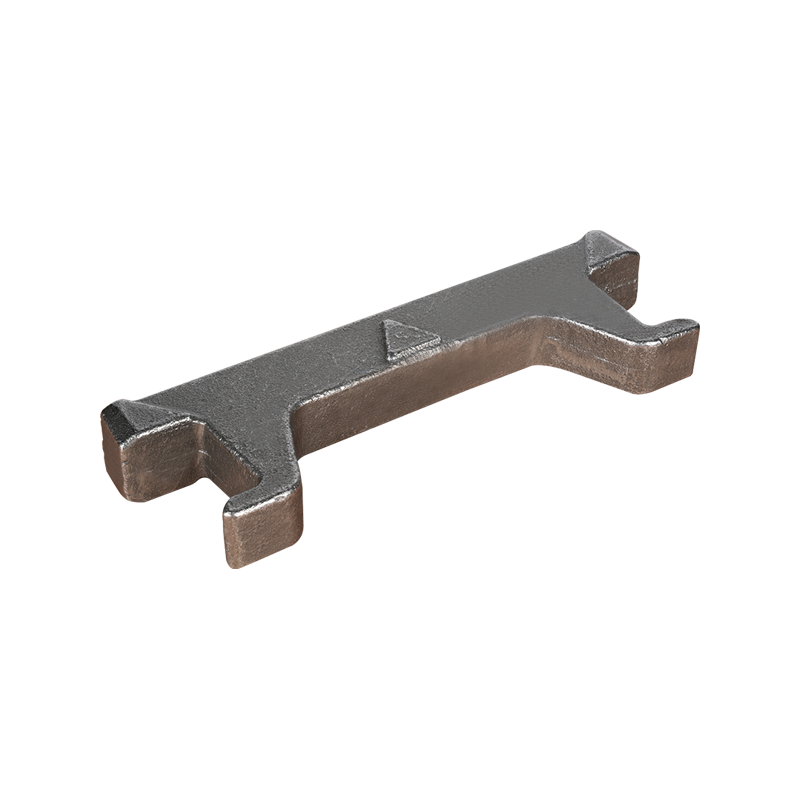

Advanced casting techniques allow for high precision in the manufacturing of complex train components. Modern casting methods, such as lost wax casting and die casting, enable engineers to design parts with intricate geometries and fine details. This flexibility is vital in designing aerodynamically efficient components, like train chassis and brake housings, which reduce air resistance and noise, thereby enhancing both performance and passenger comfort.

5. Cost-Effectiveness and Mass Production

Casting steel parts can be more cost-effective compared to other manufacturing methods, especially when producing large quantities of similar components. In high-speed train production, economies of scale are essential for keeping costs manageable. The ability to mass-produce casting steel parts with high precision and consistency ensures that manufacturers can produce large volumes of essential components without sacrificing quality.

6. Resistance to Environmental Factors

High-speed trains are subject to a range of environmental conditions, including temperature fluctuations, humidity, and corrosive elements like saltwater in coastal regions. Steel casting parts offer excellent resistance to such environmental factors. For example, casting steel can be treated to resist corrosion, ensuring the parts remain functional and safe throughout the lifespan of the train, even under harsh weather conditions.

7. Sustainability and Recycling

Steel is a highly recyclable material, and this is an important consideration in the transportation sector, which is increasingly focusing on sustainability. The casting steel used in high-speed train manufacturing can be recycled at the end of its lifecycle, contributing to a reduction in the environmental footprint of train production. Furthermore, advancements in greener steel production methods, such as electric arc furnace (EAF) technology, are making casting steel more environmentally friendly.

8. Better Thermal Management

High-speed trains generate significant amounts of heat during operation, especially in braking systems and the engine. Casting steel parts, particularly those in high-heat areas, are designed to withstand these extreme temperatures. Steel has high thermal conductivity, which helps in the efficient dissipation of heat, preventing components from overheating and maintaining optimal performance.

9. Customization for Specific Train Types

Different high-speed train models require unique components to optimize their performance. Casting steel allows for customization of parts to suit the specific demands of different rail systems, whether they are operating in urban settings, on long-distance routes, or at exceptionally high speeds. This flexibility ensures that each part is tailored to the exact specifications of the train design.

10. Long-Term Economic Benefits

While casting steel parts may involve higher upfront costs for tooling and material, the long-term economic benefits are significant. The durability, reduced maintenance needs, and efficiency improvements brought by casting steel parts result in lower operational costs and fewer downtime periods. This leads to a more cost-effective and sustainable high-speed rail service over time.

Language

Language

FT CASTING

FT CASTING