Our quality assurance services and processes ensure the reliability of our products and your satisfaction.

In the agricultural machinery field, choosing the right parts is crucial. Specifically, cast steel and cast iron parts each have their own advantages and disadvantages, directly affecting the performance, durability, and cost-effectiveness of the machinery. Understanding the differences between these two materials can help manufacturers and farmers make more informed and rational decisions.

Basic Definitions of Cast Steel and Cast Iron

Cast Steel Parts

Cast steel is a metal material produced through casting processes, usually composed of iron, carbon, and other alloying elements such as molybdenum, chromium, and silicon. Compared to ordinary carbon steel or alloy steel, cast steel parts have higher tensile strength, toughness, and impact resistance. They are widely used in agricultural machinery parts that need to withstand high loads and complex working conditions.

Cast Iron Parts

Cast iron parts are made from a combination of iron, carbon, and silicon. Compared to cast steel, cast iron generally has better casting performance and is more cost-effective. While cast iron has high compressive strength, it is more brittle and not suitable for applications where high-impact forces are involved. Cast iron is commonly used for parts such as the chassis and external casings of agricultural machinery, which need to withstand pressure but not high-impact forces.

Comparison of Mechanical Properties Between Cast Steel and Cast Iron

Mechanical Properties of Cast Steel

Cast steel has excellent mechanical properties, particularly in terms of tensile strength, toughness, and impact resistance. It typically has higher tensile strength than cast iron, making cast steel parts more capable of withstanding significant external loads. In high-strength working conditions, cast steel parts can maintain structural stability, preventing risks such as cracking or damage.

Moreover, cast steel has strong toughness, allowing it to absorb significant impact forces and exhibit good ductility under excessive load, thus preventing sudden fracture.

Mechanical Properties of Cast Iron

Cast iron generally has higher compressive strength, but it lacks the necessary toughness. It is more brittle and tends to crack or break under impact forces. As such, cast iron parts are suited for applications where uniform pressure is applied but are not ideal for environments requiring frequent shock loading.

In terms of mechanical properties, cast steel is better suited for agricultural machinery parts exposed to high loads and impact forces, while cast iron is more appropriate for applications under static loads.

Comparison of Wear Resistance Between Cast Steel and Cast Iron

Wear Resistance of Cast Steel

Cast steel generally has good wear resistance, especially in high-alloy cast steel, where wear resistance is significantly enhanced. However, when compared to cast iron, cast steel’s wear resistance is not as outstanding because cast iron’s graphite structure provides self-lubricating properties that reduce friction, thereby extending the life of the parts.

Wear Resistance of Cast Iron

Due to its high graphite content, cast iron has excellent wear resistance and self-lubricating properties, which make it ideal for high-friction environments. For example, in soil-working components of agricultural machinery, cast iron can better withstand prolonged wear and reduce the need for frequent maintenance.

Comparison of Corrosion Resistance and High-Temperature Resistance Between Cast Steel and Cast Iron

Corrosion and High-Temperature Resistance of Cast Steel

Cast steel generally has superior corrosion and high-temperature resistance compared to cast iron. This is due to the addition of elements such as chromium and molybdenum in cast steel, which provide excellent high-temperature resistance and improve its corrosion resistance. Therefore, cast steel is suitable for high-temperature and chemically corrosive environments, such as engine parts and transmission systems.

Corrosion and High-Temperature Resistance of Cast Iron

Cast iron typically has poorer corrosion resistance, especially in humid environments, where it is more likely to rust. However, in general agricultural machine environments, cast iron’s corrosion and high-temperature resistance is sufficient for most conditions. Due to its lower temperature tolerance, cast iron parts are not suitable for high-temperature work environments.

Comparison of Weight Between Cast Steel and Cast Iron

Weight of Cast Steel

Cast steel has a higher density, so its parts are generally heavier than cast iron parts. In agricultural machinery that requires lightweight operation, the heavier weight of cast steel parts may affect performance, particularly in applications that aim to reduce the machine’s overall weight.

Weight of Cast Iron

Cast iron has a lower density than cast steel, so cast iron parts are relatively lighter. In applications that require the machine to be lightweight, cast iron parts offer advantages. However, the lighter weight of cast iron may not perform well under high-strength or impact-heavy conditions.

Cost Comparison Between Cast Steel and Cast Iron

| Material | Cast Steel | Cast Iron |

|---|---|---|

| Cost | Relatively high, due to complex process | Relatively low, more cost-effective |

| Durability | Long service life, suitable for high-strength applications | Good wear resistance, but prone to damage |

| Suitability | Suitable for parts in high-load, complex environments | Suitable for low-load, low-impact parts |

| Weight | Heavier parts | Lighter parts, suitable for weight reduction |

Cost of Cast Steel

Cast steel generally has higher manufacturing costs due to more complex processes and the use of alloy materials. Specifically, high-alloy cast steel materials can be quite expensive. However, because cast steel parts offer superior performance and longer service life, they reduce maintenance and replacement costs over the long term. Therefore, for parts that need to withstand high-strength, complex loads, cast steel is a worthy investment.

Cost of Cast Iron

Cast iron is more cost-effective due to simpler manufacturing processes and cheaper raw materials. For applications with a limited budget and less stringent performance requirements, cast iron offers a good alternative. However, due to its brittleness, cast iron parts may require more frequent replacement and maintenance over time, leading to higher long-term costs.

Suitable Applications of Cast Steel and Cast Iron

Suitable Applications for Cast Steel

Cast steel parts are ideal for agricultural machinery that operates under high loads, frequent impacts, or extreme working conditions. Examples include the transmission systems, lifting components, and high-load bearing parts of heavy-duty machinery. Cast steel is also suitable for high-temperature, corrosive environments, where it can effectively resist external environmental damage.

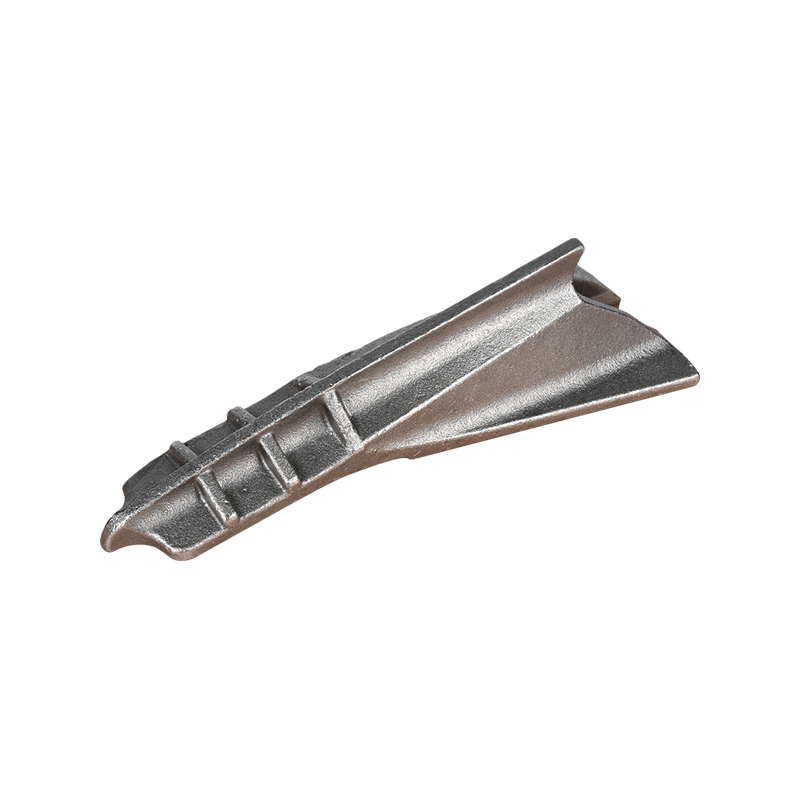

Suitable Applications for Cast Iron

Cast iron parts are commonly used in agricultural machinery parts that experience static loads and need to resist wear, such as tillage blades, chassis, and casings. Given cast iron’s excellent wear resistance and compressive strength, it is effective in applications that don’t require frequent exposure to high-impact forces.

How to Choose the Right Material?

Choosing between cast steel and cast iron largely depends on the working environment and performance requirements of your agricultural machinery. If your machinery operates under high loads, frequent impacts, and in high-temperature or corrosive environments, cast steel would be a better option. On the other hand, if your equipment mainly operates under low-load, wear-resistant conditions, and budget is a concern, cast iron parts may provide the best value.

Language

Language

FT CASTING

FT CASTING